In search of the dark side of the universe

How did the universe come about and what is it made of? As a response to these questions the European space telescope Euclid was brought to life by ESA. From 2022 Euclid’s mission is to explore the “dark side” of the universe. Euclid, with its 1.2 meter wide telescope and two instruments – an optical imager (VIS) and a spectrograph and photometer for the near infrared (NISP) –, will observe the universe with unprecedented precision in search of dark energy and dark matter. Both phenomena are still largely unexplored, but without their existence the structure of the universe cannot be explained. ESA aims to have Euclid’s measurement results and stored telemetry data sent via a movable antenna to the ground station at Cebreros in Spain when the telescope is visible from Earth.

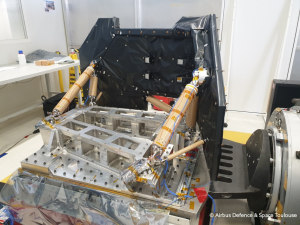

INVENT GmbH specialized in innovative lightweight structures projects in the aerospace industry has been contracted by Airbus Defence and Space to manufacture, assemble and qualify support struts made of glass fiber reinforced plastic (GFRP), Titanium and Invar for the two instruments VIS and NISP and the entire payload module. “The PLM/SVM struts are the interface between the platform and the payload, while the VIS and NISP structure are supports for the instrument radiators. Their key requirement beside the mechanical support function is to ensure that the particularly sensitive telescope is not influenced by the satellite bus and the instrument radiators- neither mechanically nor thermally. The platform and radiators can basically “breathe” and expand without impacting the instruments.” explains Christoph Tschepe, Head of Space Business Unit at INVENT. The sophisticated hardware had to be mechanically and thermally qualified down to 70 K.

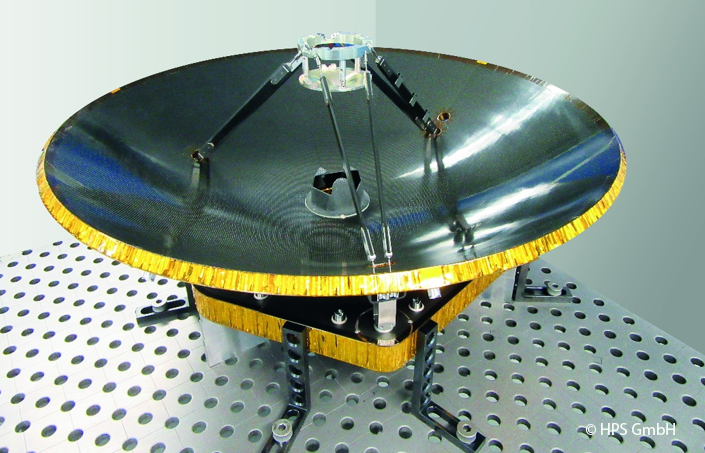

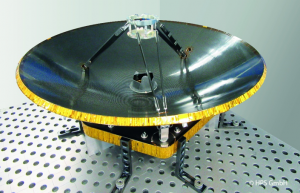

In addition, INVENT has manufactured the composite structure for the so-called, High Gain Antenna ARA (antenna reflector assembly). This is the main antenna for the transmission of the data – and was manufactured on behalf of HPS GmbH. The flight model has now been delivered by HPS to the main contractor responsible for the construction of the spacecraft, Thales Alenia Space. “ARA is a key component of the mission. The high performance reflector weighs 4.5 kilograms and due to the compactness of the antenna and the strong curvature of the reflector, it is required to be made from extremely light, yet stable materials. We have developed this structure together with HPS and manufactured it in our facilities. ”reports Christoph Tschepe.

Euclid will observe roughly half of the sky and penetrate up to ten billion light-years deep into space. Only about five percent of the mass of the universe is known to date, the rest consists of dark matter and dark energy. Dark matter is invisible and only by the action of its gravity is it recognizable. The dark energy causes the universe to expand with increasing acceleration. The measurements and images of the optical camera (VIS) will observe geometric distortions in the shape of the galaxy caused by dark matter, the spectro– and photometer and the NISP will measure galaxies based on brightness and redshift, so that the relative distances of galaxies can be calculated.

About INVENT

PASSION FOR COMPOSITES

As a recognized lightweight construction specialist for innovative fiber composite technologies in the aerospace, mechanical engineering and automotive industries, INVENT GmbH in Braunschweig has been developing high-precision structural components, from the first idea to series production since 1996. The company’s own designers and constructors work very closely with a wide variety of manufacturing specialists. We offer our customers a complete package from a single source with a view to design, materials, manufacturing planning, manufacturing processes, mechanical processing, joining and assembly as well as painting and quality control. We are an EN 9100 and Nadcap certified company.

www.invent-gmbh.de

About Euclid

As a recognized lightweight construction specialist for innovative fiber composite technologies in the aerospace, mechanical engineering and automotive industries, INVENT GmbH in Braunschweig has been developing high-precision structural components, from the first idea to series production since 1996. The company’s own designers and constructors work very closely with a wide variety of manufacturing specialists. We offer our customers a complete package from a single source with a view to design, materials, manufacturing planning, manufacturing processes, mechanical processing, joining and assembly as well as painting and quality control. We are an EN 9100 and Nadcap certified company.