INVENT GmbH manufactures the “nose boom” for the new TU Braunschweig research aircraft

In the year of its 275th birthday, the Technische Universität Braunschweig is receiving a very special “new addition” – a further research aircraft. The second-hand Cessna F406, which has spent the last 15 months being converted for scientific missions, bears the registration “D-ILAB” and is a twin-engine, lightweight multi-purpose and commuter aircraft with propeller turbines and was built by the French manufacturer ASI AVIATION Reims.

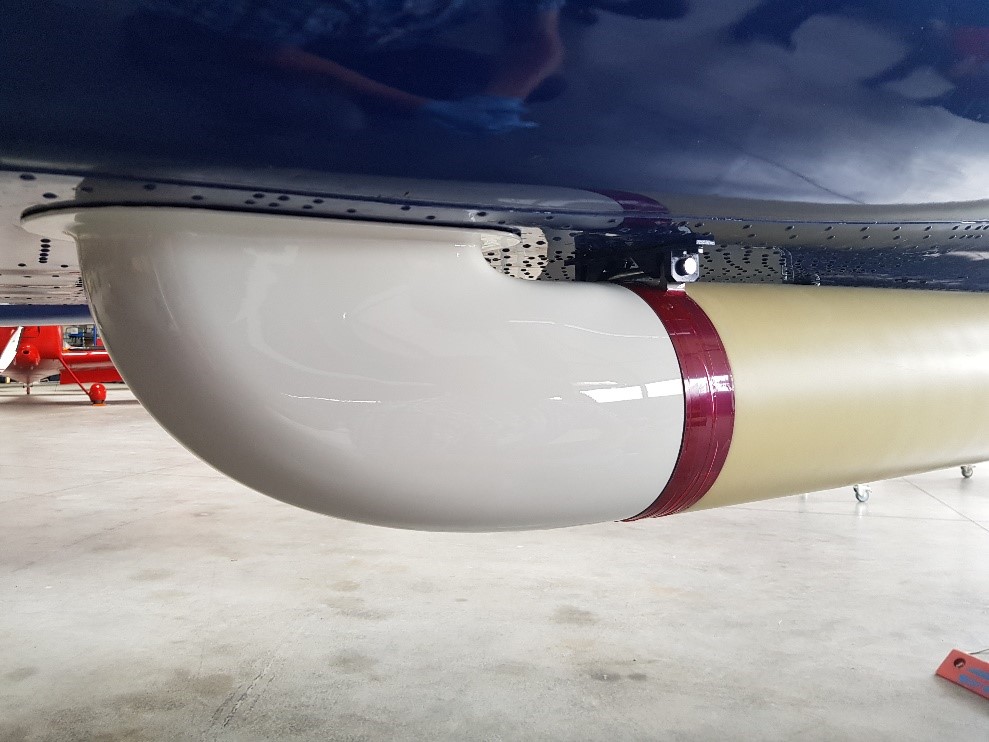

INVENT GmbH from Braunschweig, Germany specialises in innovative lightweight construction for aerospace applications and has supported the conversion of the Cessna into a research aircraft by designing, manufacturing, testing and installing the so-called nose boom, which is made from CFRP and other materials, underneath the aircraft’s “nose”. “Over the past 20 years, we have designed and manufactured several of these nose booms for a wide variety of research aircraft – including the research fleet of the German Aerospace Center and the Dornier Do 728 nose boom. With the latter we have, in a manner of speaking, already written aviation history,” explains Stefan Steeger, Head of Aviation and D-ILAB Project Manager at INVENT.

“What is particularly exciting is the individual equipment of research aircraft and other airborne vehicles for special tasks and the adaptation to the respective aircraft. Our experience thereby ranges from nose booms, housings and conversions for e.g. cameras and other devices in the fuselage through to trailing cones which, towed along far behind the aircraft, also allow measurements in the airstream.”

The boom for “D-ILAB” is 4.5 meters long and protrudes around two meters below the nose of the aircraft. “It serves to place sensors in front of the aircraft in order to carry out scientific measurements in the undisturbed incident flow, where possible,” explains Stefan Steeger. Wind direction, wind speed and turbulence can, for example, be recorded, as well as the temperature and moisture content of the air.

In the medium term, “D-ILAB” is to become the successor to the “D-IBUF” research aircraft of the Technische Universität, which has been in service for more than 30 years for the “Carolo Wilhelmina” and is the last Dornier of the type “Do 128-6” still flying.

The youngest member of the TU research fleet was transferred from Reims to Braunschweig on 8th July 2020. “We are now assembling the prefabricated modules at the airport in Braunschweig; the nose boom includes the measuring head and cowlings, which we also produced at INVENT. In addition, we will bond a support ring to the “D-ILAB” once the boom has been precisely aligned. The final painting work will be carried out once all the adjustments have been completed,” says Stefan Steeger. Following further test flights in August, the final certification of the research aircraft is scheduled for September.

The conversion of the Cessna F406 began after the university acquired the aircraft last year. In December 2019 the new paint scheme was ready, followed by the complete interior outfitting with the conversion of the cockpit, the installation of the measuring sensors including cabling, and the configuration of two scientific workstations which can be used flexibly. The range of the modernized Cessna is 2200 kilometres. According to the TU Braunschweig, “D-ILAB” will be used in the future for various disciplines, in particular for meteorological issues such as thunderstorm research, sea-ice processes in the Arctic or the impact of offshore wind farms on the atmosphere.

About INVENT

Passion for Composites

As a recognized lightweight construction specialist for innovative fibre composite technologies in the aerospace, mechanical engineering and automotive industries, INVENT GmbH in Braunschweig has been developing high-precision structural components, from the first idea to series production since 1996. INVENT’s designers and engineers work very closely together with in-house production specialists from the most diverse sectors. We are therefore able to offer our customers a complete package from a single source with regard to design, production planning, manufacturing processes, machining, joining and assembly as well as coating/painting and quality control.

www.invent-gmbh.de

cover picture: D-ILAB has arrived in Braunschweig [Source: Kristina Rottig/TU Braunschweig]