SPACE

Space is one of the main fields of application for the company’s core competence, fibre composite lightweight design. INVENT has more than 20 years of experience in the development, production and qualification of sophisticated space hardware, which finds applications in conventional satellites, small satellites, probes, rovers as well as space stations and launch vehicles.

The product spectrum ranges from monolithic fibre composite and metal components to complex multi-material structures.

In a typical development of a spacecraft structure, we can take over or accompany different steps, e.g. design & analysis, manufacturing, assembly of optical instruments or satellite primary structures. Together with a broadly positioned and modern machine park and a certified quality management system, we thus offer many solutions from a single source.

To stay at the cutting edge of technology, INVENT implements ambitious research and development projects together with partners. These primarily focus on material development, design, 3D printing, multifunctional structures as well as tests of functional demonstrators and prototypes for testing in space.

Satellites with our Products

Satellites with our products

90+

Missions in space

Missions in space

60+

Structures smallest/largest

Structures

smallest/largest

2cm3/16m3

In-House Production

In-House production

95%

Farthest Parts

Farthest parts

198 Mio. km

Temperature lowest/Highest

Temperature

lowest/highest

-271°C/180°C

In Space since

In space since

2007

Flying Parts

Flying parts

11.000+

PRODUCTS AND SERVICES

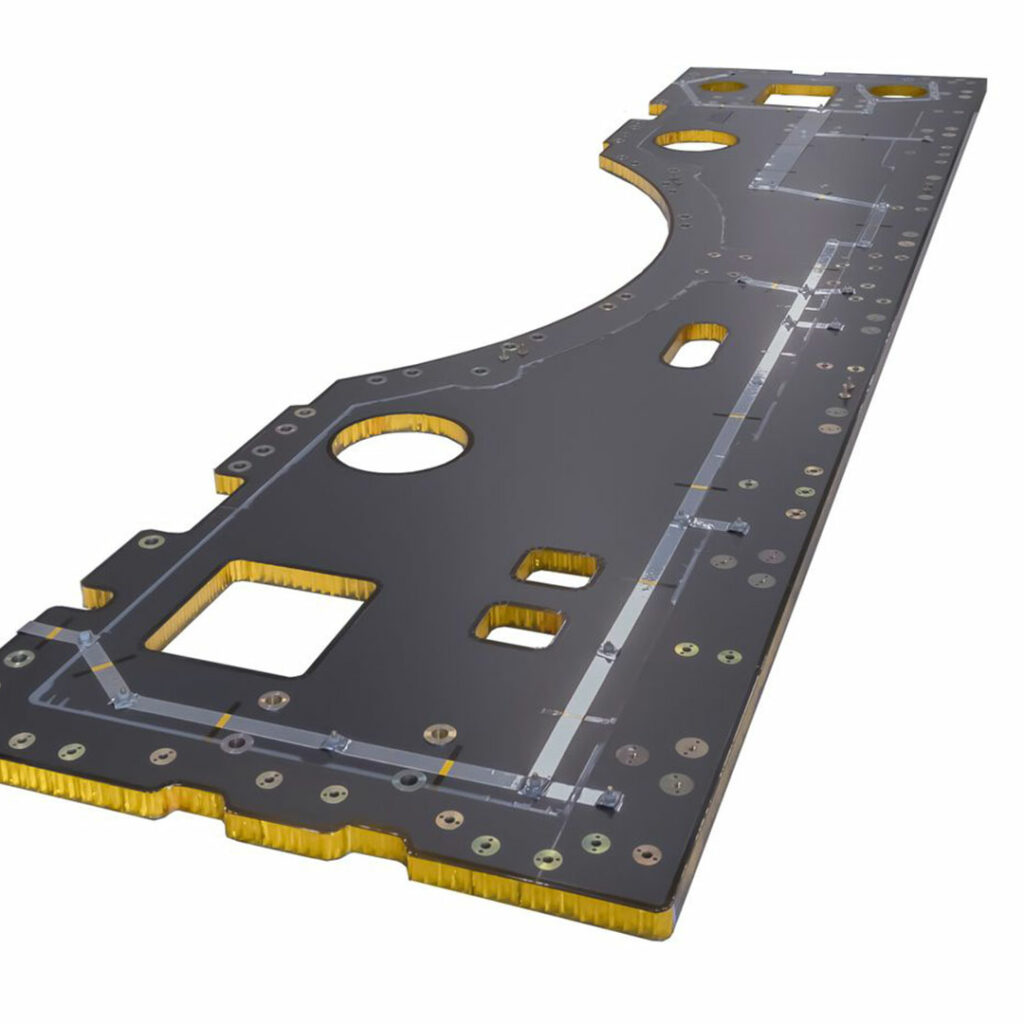

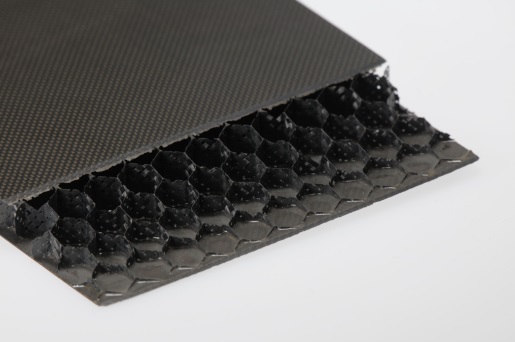

Structural panel

Flat structural panels based on CFRP or aluminium facesheets and honeycomb cores are classic structural elements of spacecrafts. INVENT’s product portfolio for prototype and series production includes the following structural panel properties:

- CFRP or aluminum face sheets

- min. min. facesheet thickness 0.1 mm

- max. dimensions 4 x 2,5 m

- Heterogeneous honeycomb structure

- Local structural doublers

- Hot and cold bonding processes for inserts (different types)

- Grounding

- Surface coatings (optical, thermal, electrical)

- Suitable for high temperature applications

References:

- ExoMars TGO

- Sentinel 4

- Solar Orbiter

- eROSITA

- ELECTRA

- Galileo FOC

- Sarah

- FormoSat-5

- Heinrich Hertz

- MTG

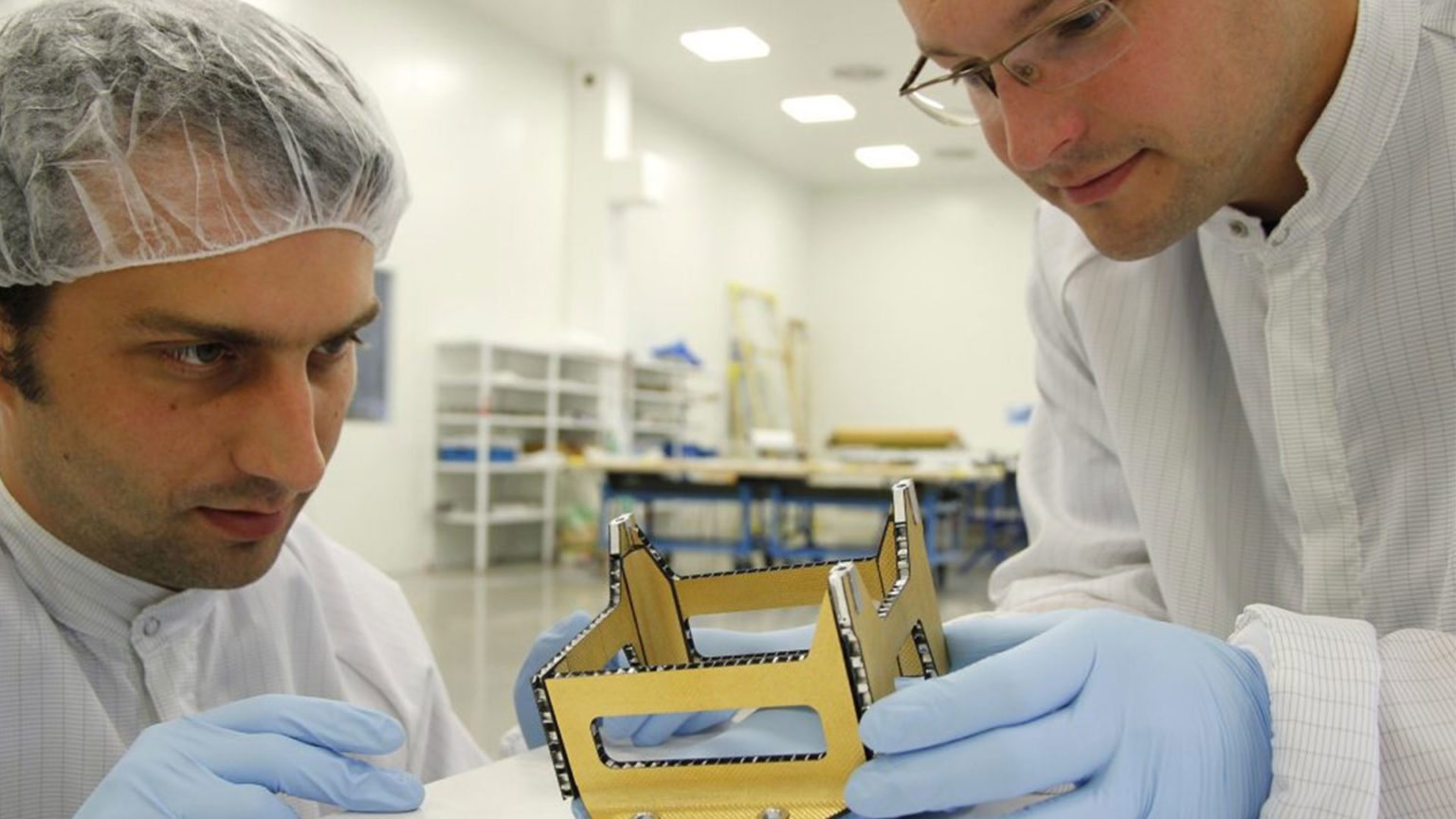

SUPPORT STRUCTURES

Primary structural elements of spacecraft and their equipment are partly supported by other, smaller components, so-called support or tertiary structures. INVENT offers here:

- Development of individual design solutions

- GFRP / CFRP and metallic (Al, Ti, Invar) structures

- Isostatic mounts

- Surface coatings on metal and CFRP (thermal, optical, electrical)

- (Partial) assembly

References:

- ExoMars

- MTG

- Metop-SG

- eROSITA

- Herschel

- EnMap

- Bepi Colombo

- SWARM

- MicroCarb

- PLATO

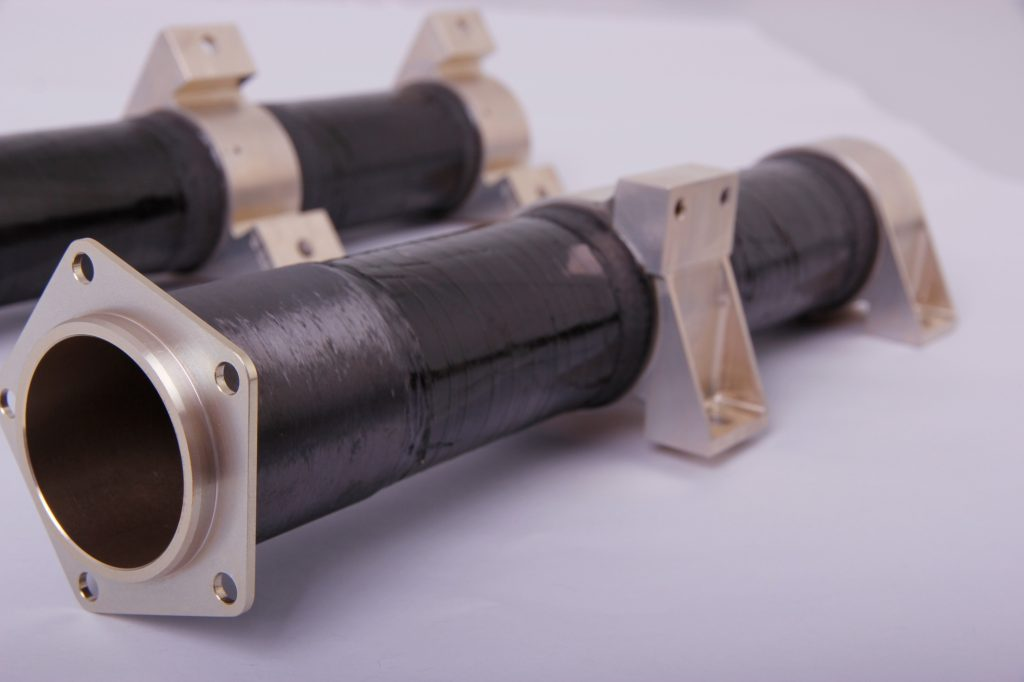

CYLINDERS, STRUTS AND BOOMS

Structures such as booms, struts and cylinders are another important design element for spacecraft design. INVENT’s services include:

- CFRP & GFRP struts with metal fittings

- Fully integral CFRP struts

- Boom (up to 3.5 m in length in one piece)

- Monolithic and sandwich central cylinders

- High flexibility in terms of materials, layup and sizes

- Suitable for extreme (hot and cold) temperature applications

References:

- Metop-SG

- JUICE

- MTG

- EDRS-C

- ExoMars TGO & Rover

- eROSITA

- Solar Sail

- CIMR

THERMAL HARDWARE

The dissipation of heat or the thermal insulation of certain components in the space environment requires special thermal hardware such as radiators or support structures with adjustable thermal conductivity. Typical product characteristics are:

- highly conductive materials: aluminium, copper, highly conductive CFRP (e.g. made of K13 fibres) or graphite foils

- Low conductive materials: Invar, titanium, GFRP

- Monolithic components

- Sandwich radiators with heat pipes, surface coating and OSRs

References:

- ExoMars TGO

- eROSITA

- Sentinel 1

- Grace FO

- TerraSAR-X

- Tandem-X

- Herschel

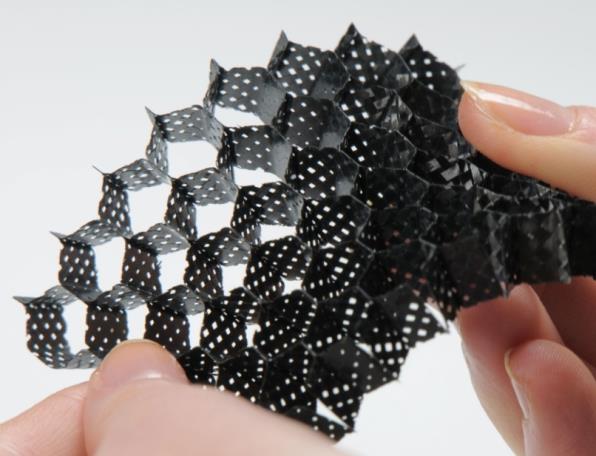

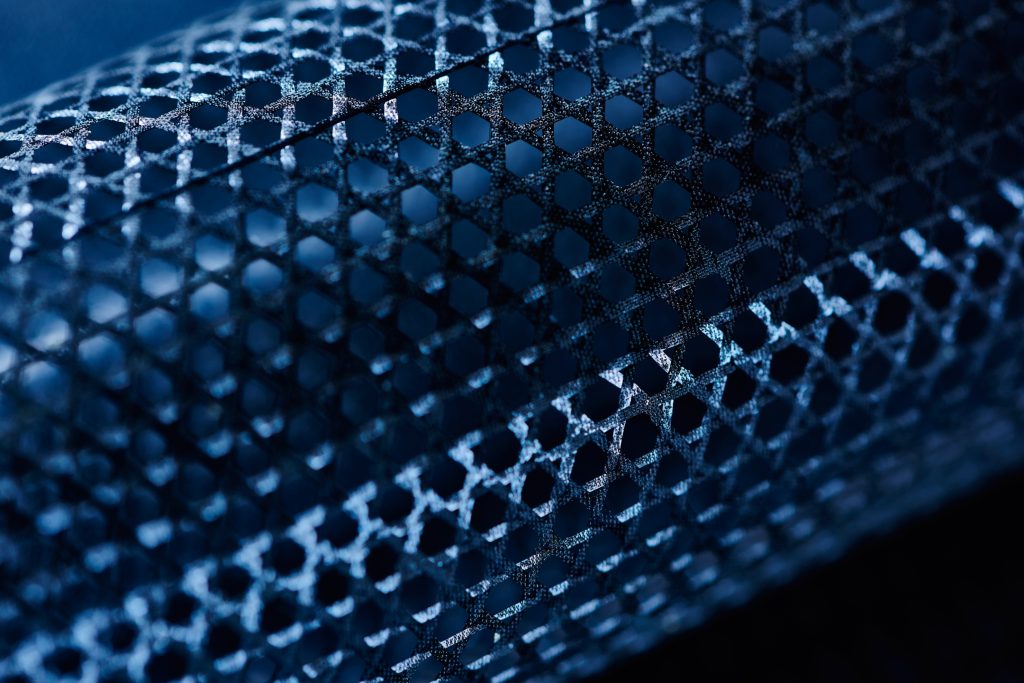

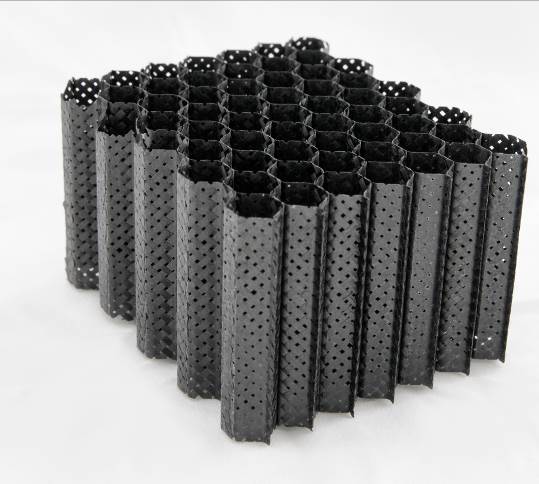

Carbon Fibre Honeycomb CCORE®

Sophisticated space structures, for example antenna reflectors or optical benches, require special materials to meet the demands placed on them.

INVENT has developed a carbon fibre honeycomb with a low coefficient of thermal expansion and high stiffness to significantly improve the thermoelastic stability of these structures. The main features of CCORE® are:

- Low outgassing

- High stiffness

- Compatible with vacuum (venting possibilities)

- Various material configurations available as commercial product

- Low heat exchange coefficient

References:

- H2Sat

- ExoMars Rover

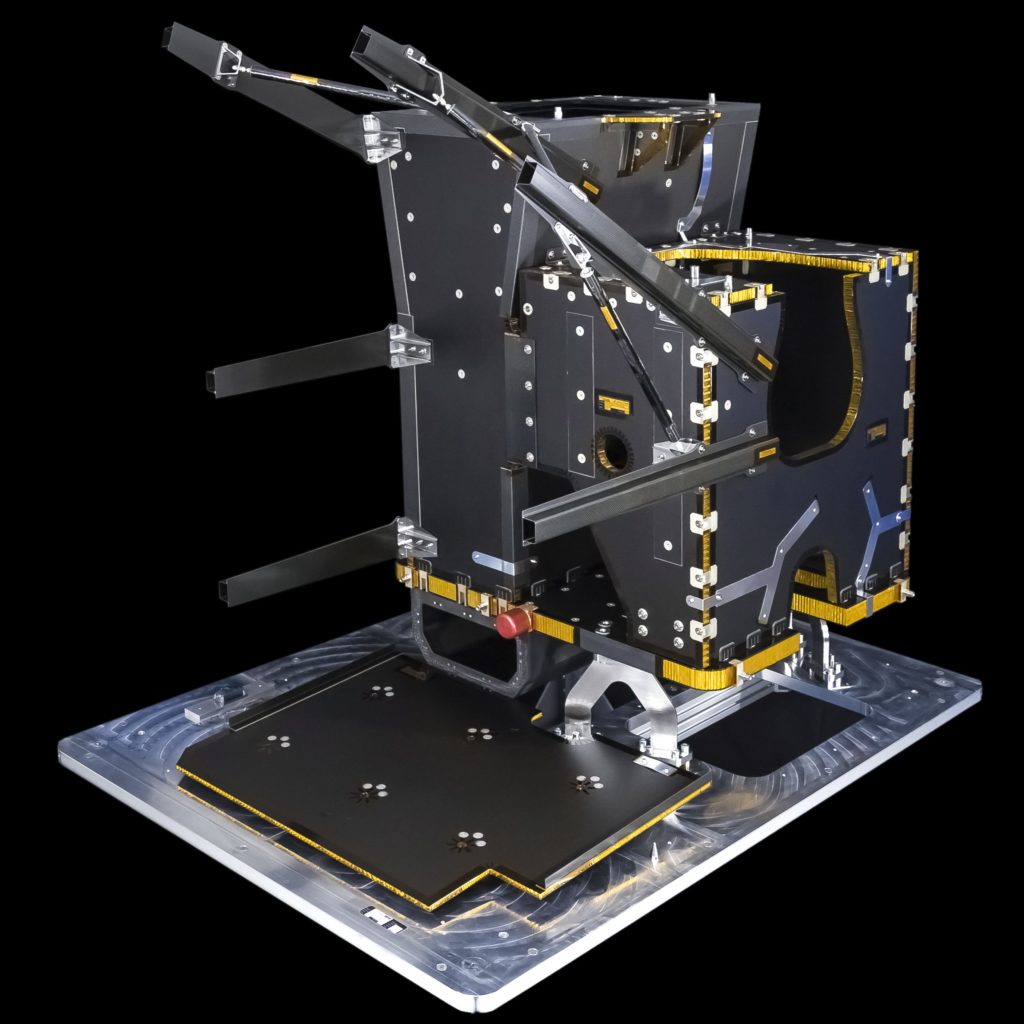

INSTRUMENT ASSEMBLIES

Instrument structures consisting of a combination of several structural components, for example sandwich panels, struts, CFRP / GFRP / metal brackets. INVENT has many years of experience in the assembly of structures and can offer the following services:

- In-house production or procurement of all structural components

- Structure assembly, alignment and inspection up to three metres in size

- Joining techniques as adhesive bonding, screwing and riveting

References:

- eROSITA

- Sentinel 4

- Sentinel 5 / 5P, MWS

- Metop-SG (3MI)

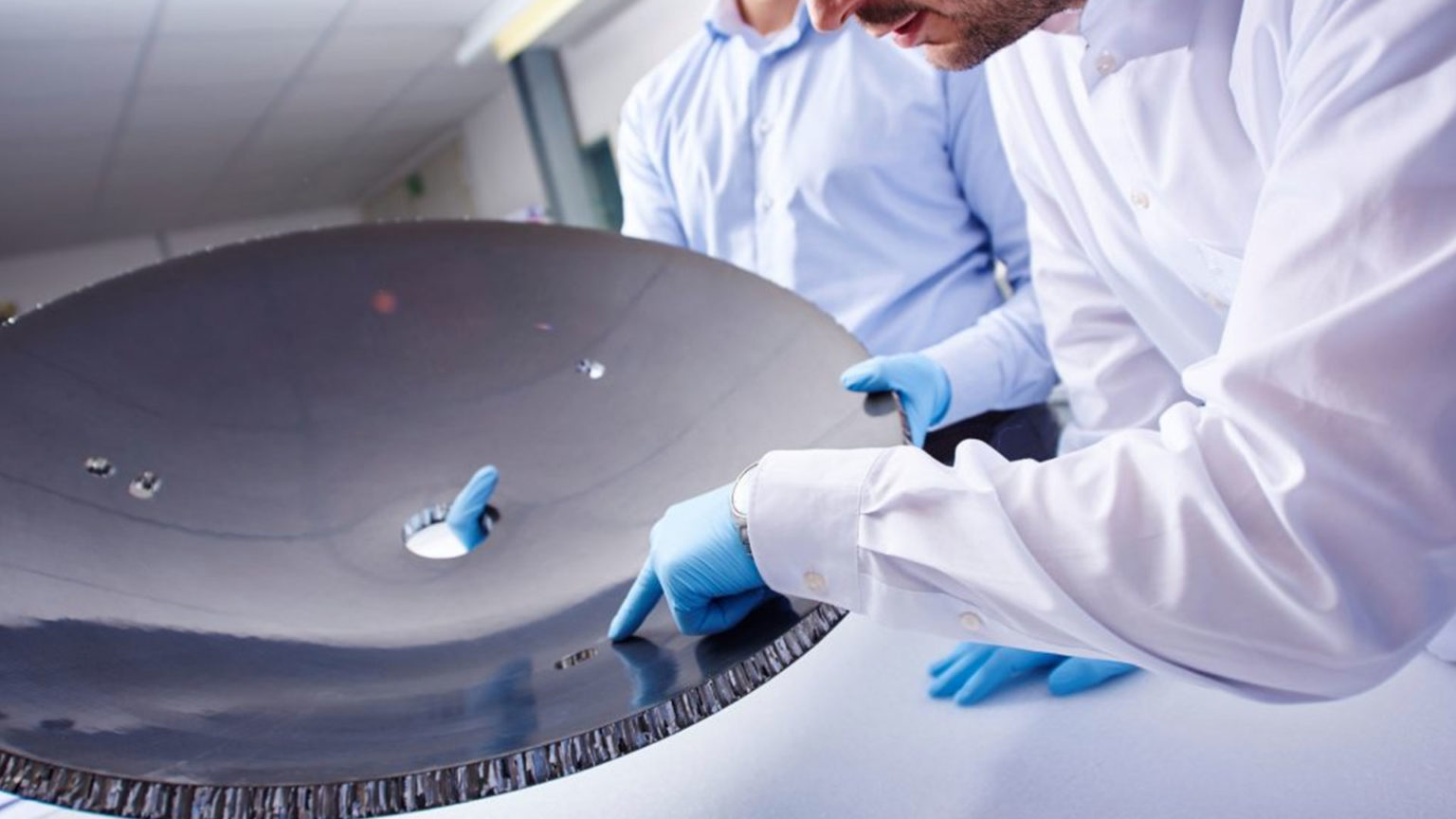

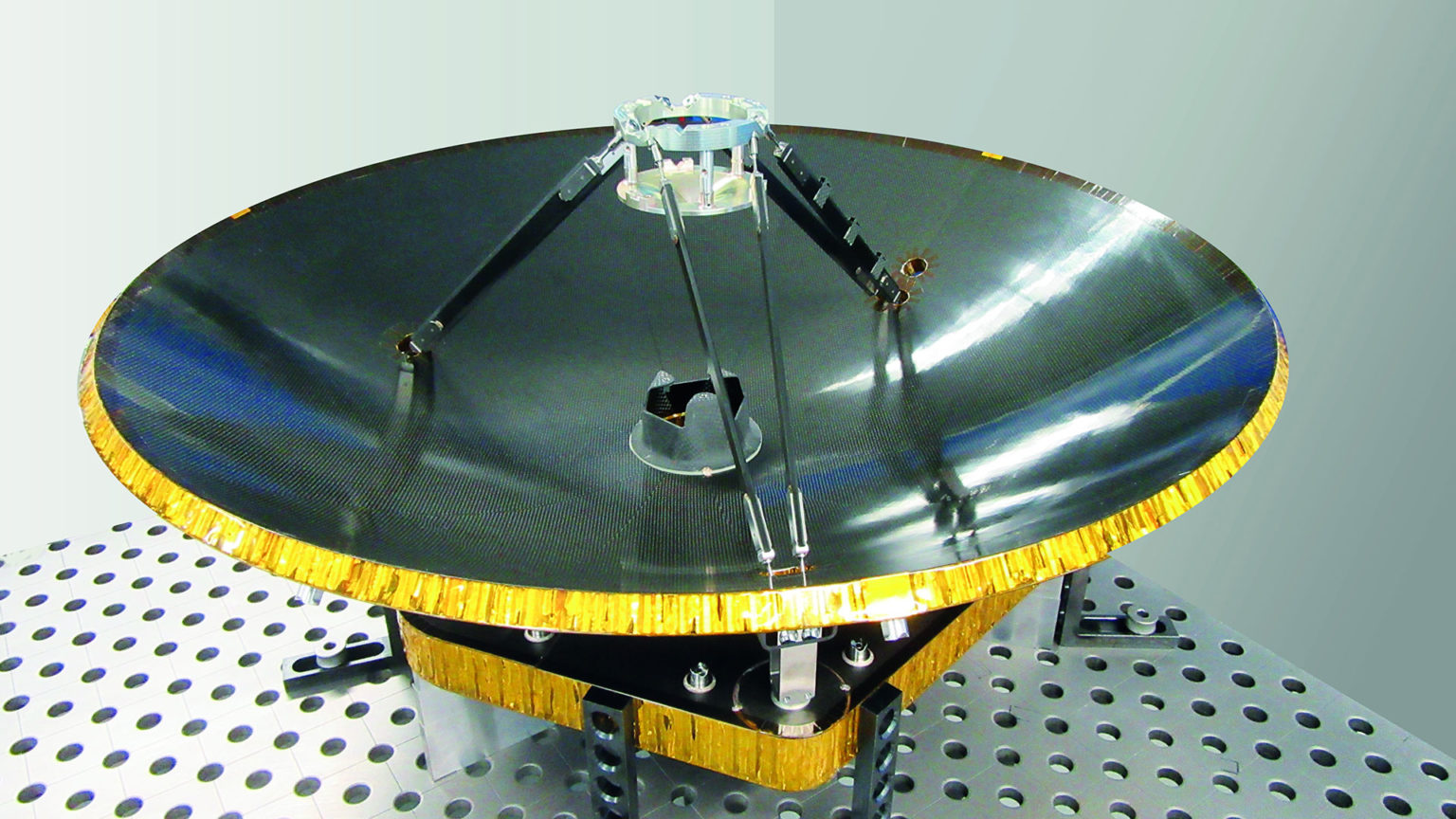

Antenna Components

- CFRP antenna reflectors up to 2.4 m

- CFRP / CFRP sandwich design components made of UHM fibres for highest thermoelastic stability, see CCORE

- CFRP waveguides in series production

- Grid antennas

- Antenna booms

- Metallisation of fibre composite parts (via suppliers)

- (Partial) assembly

References:

- TerraSAR-X

- Tandem-X

- EUCLID HGA

- Exomars Rover

- Heinrich Hertz H2KAR

- verschiedene ESA Artes Studien

VIDEO

INVENT Space Business

OTHER SECTORS

AVIATION

INDUSTRY AND INNOVATION

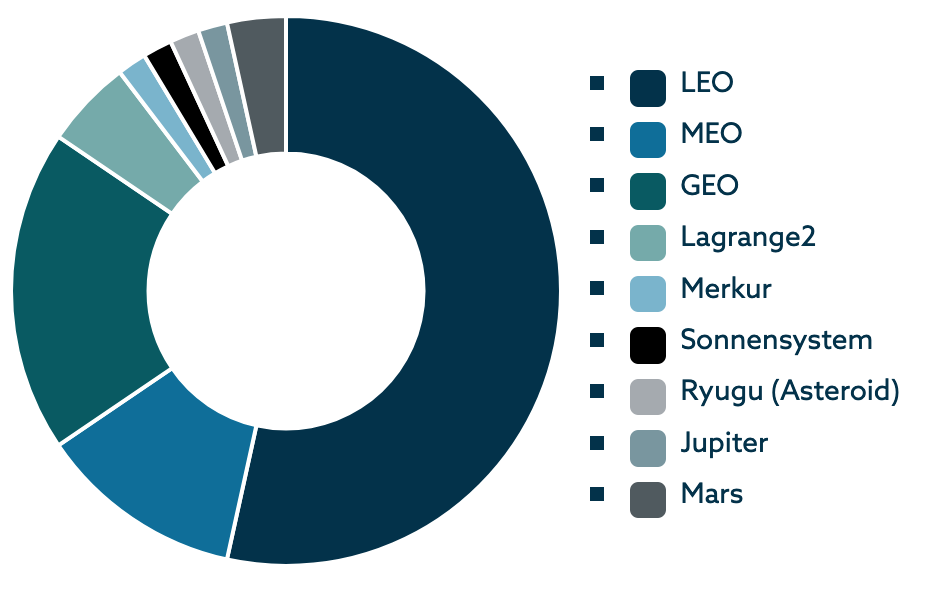

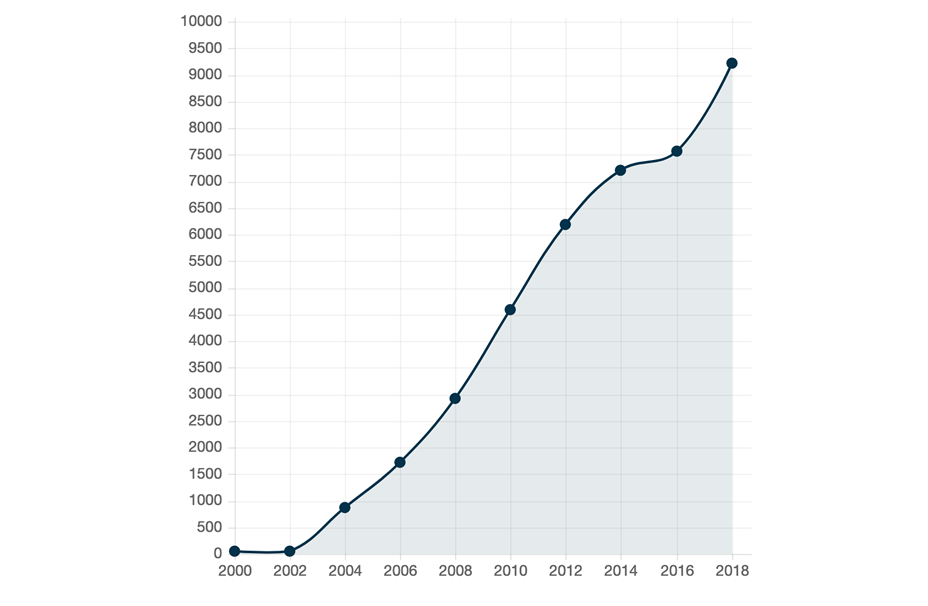

SPACE IN NUMBERS

MISSION GOALS (TOTAL 58)

INVENT-PARTS IN SPACE

CONTACT

Dipl.-Ing.

Christoph Tschepe

Phone +49 531 24466-20

christoph.tschepe@invent-gmbh.de