INDUSTRY & INNOVATION

The Industry & Innovation unit has been established to develop technologies for new applications and markets regarding the use of fibre composite materials as well as the development of future technologies for lightweight components in general. In the field between sustainability, industrialisation and economic efficiency, we transfer the potential of high-performance fibre composites to new industries and applications and thus meet the high customer requirements for e.g. stiffness, dimensional stability in a large temperature ranges and optimal process routes for different batch sizes.

An interdisciplinary team takes over responsibility for these challenges, covering the spectrum from materials science, process technology, design and simulation to mechatronics. Here, strategic research topics, market analyses and customer discussions merge in internal workshops into ideas that demonstrate suitability of high-performance fibre composite structures in new applications – in a sustainable and economical way.

Market & Services

Machinery and industry

Machinery and industry

Carbon fibre reinforced plastics (CFRP) also have a raison d’être in mechanical engineering. Components that are operated in large temperature ranges can be realised with dimensional stability, for example, and thus allow higher precision. The lower mass allows smaller, cost-effcient and energy-saving actuation.

The challenge is to implement the higher performance in existing structures or under non-variable boundary conditions. The transfer of metallic designs to CFRP without adaption to the material specific properties is usually not reasonable (“black metal design”).

From concept to design and prototypes to series production, INVENT is your one-stop contact for the fibre composite compatible realisation of your components.

References:

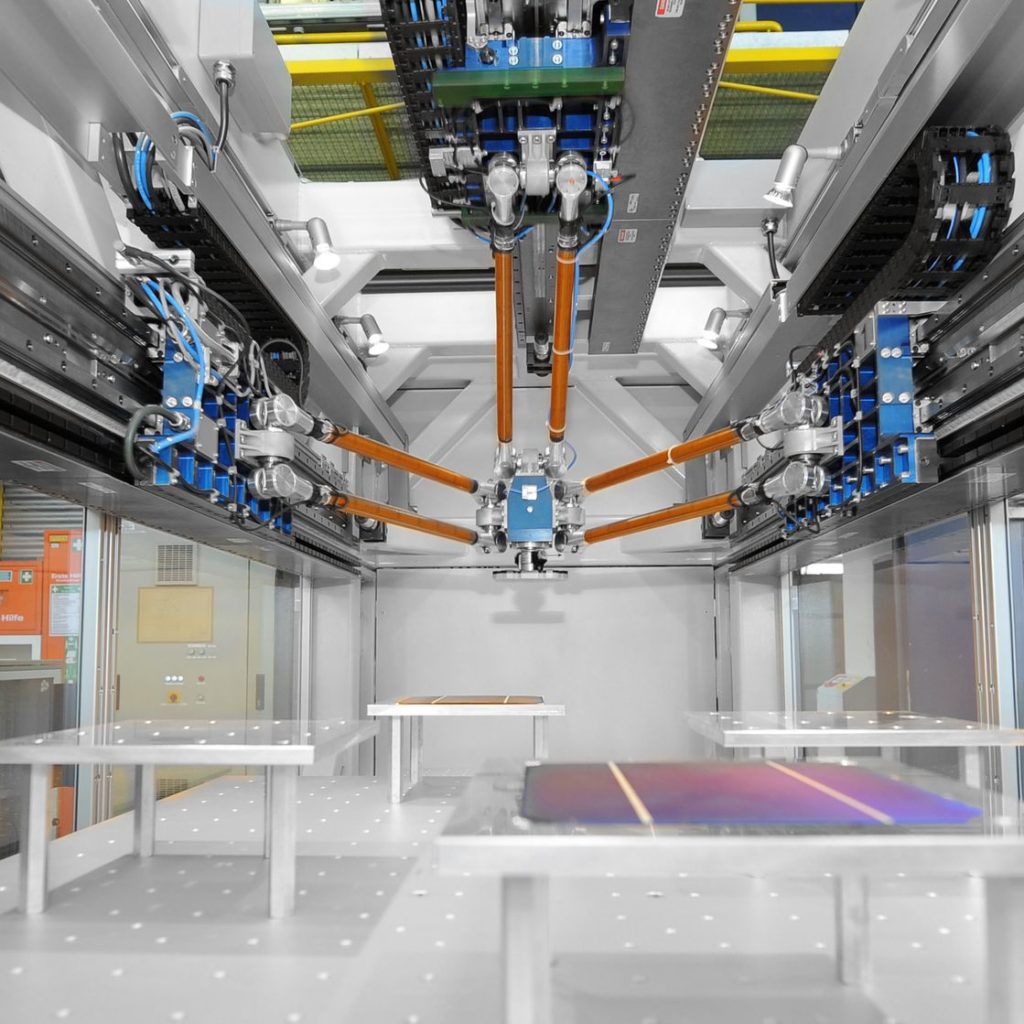

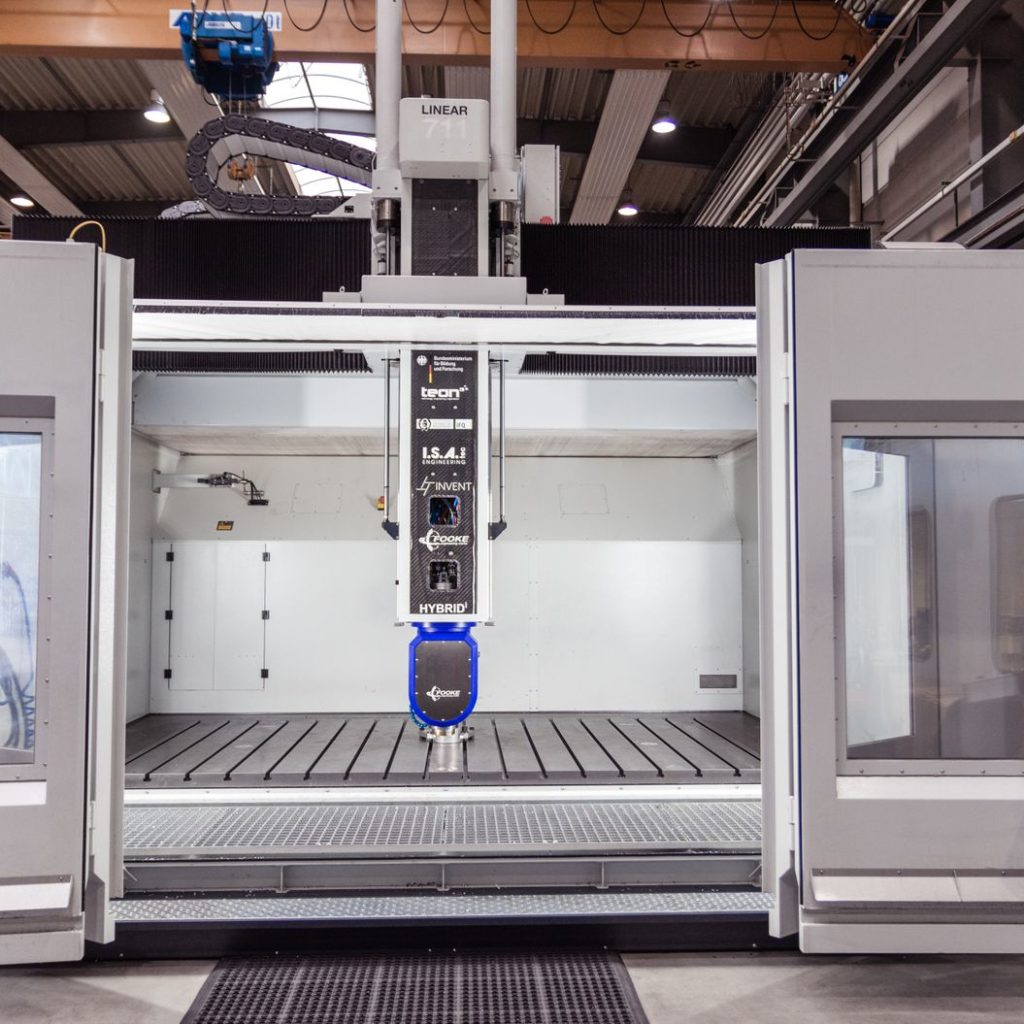

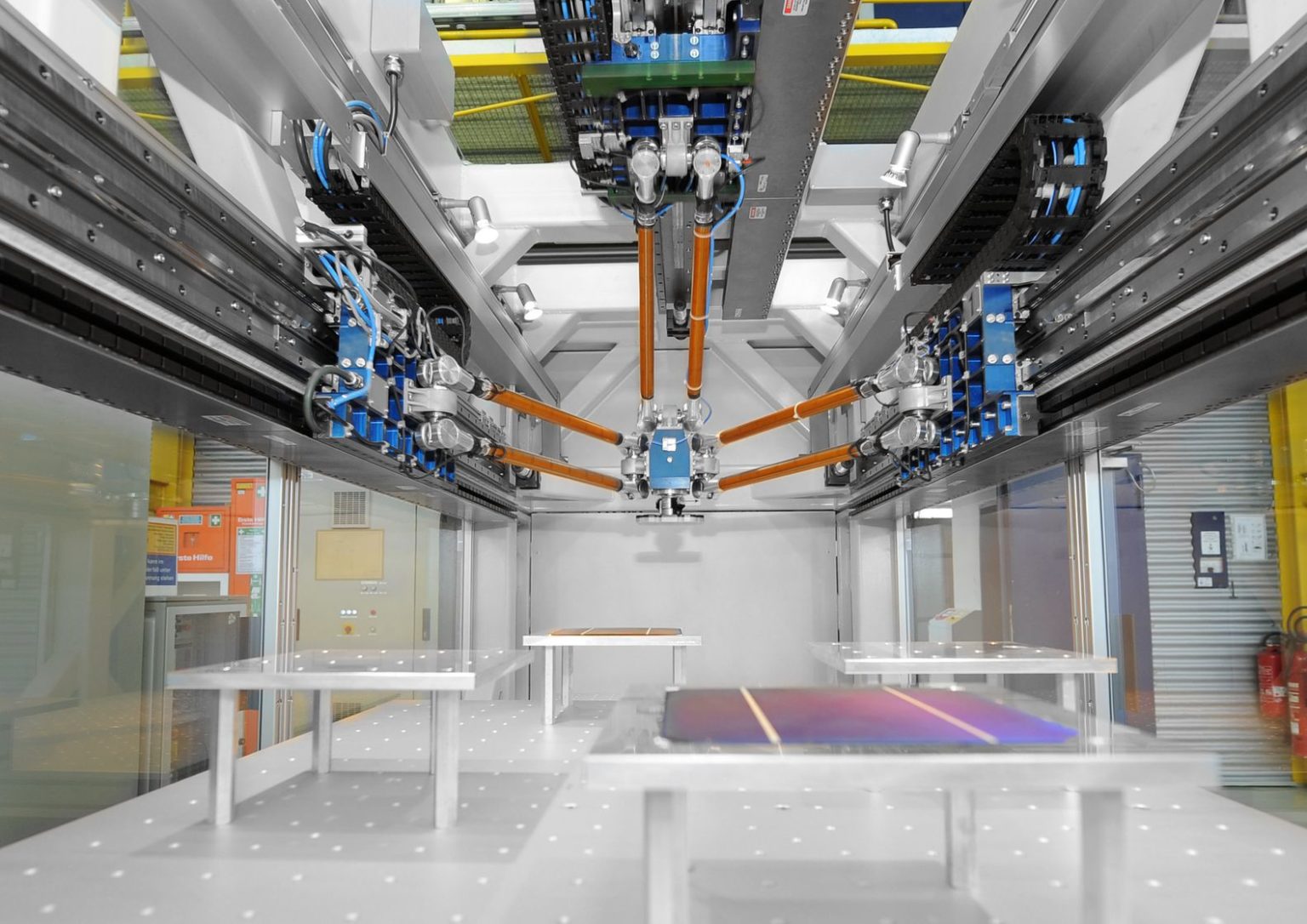

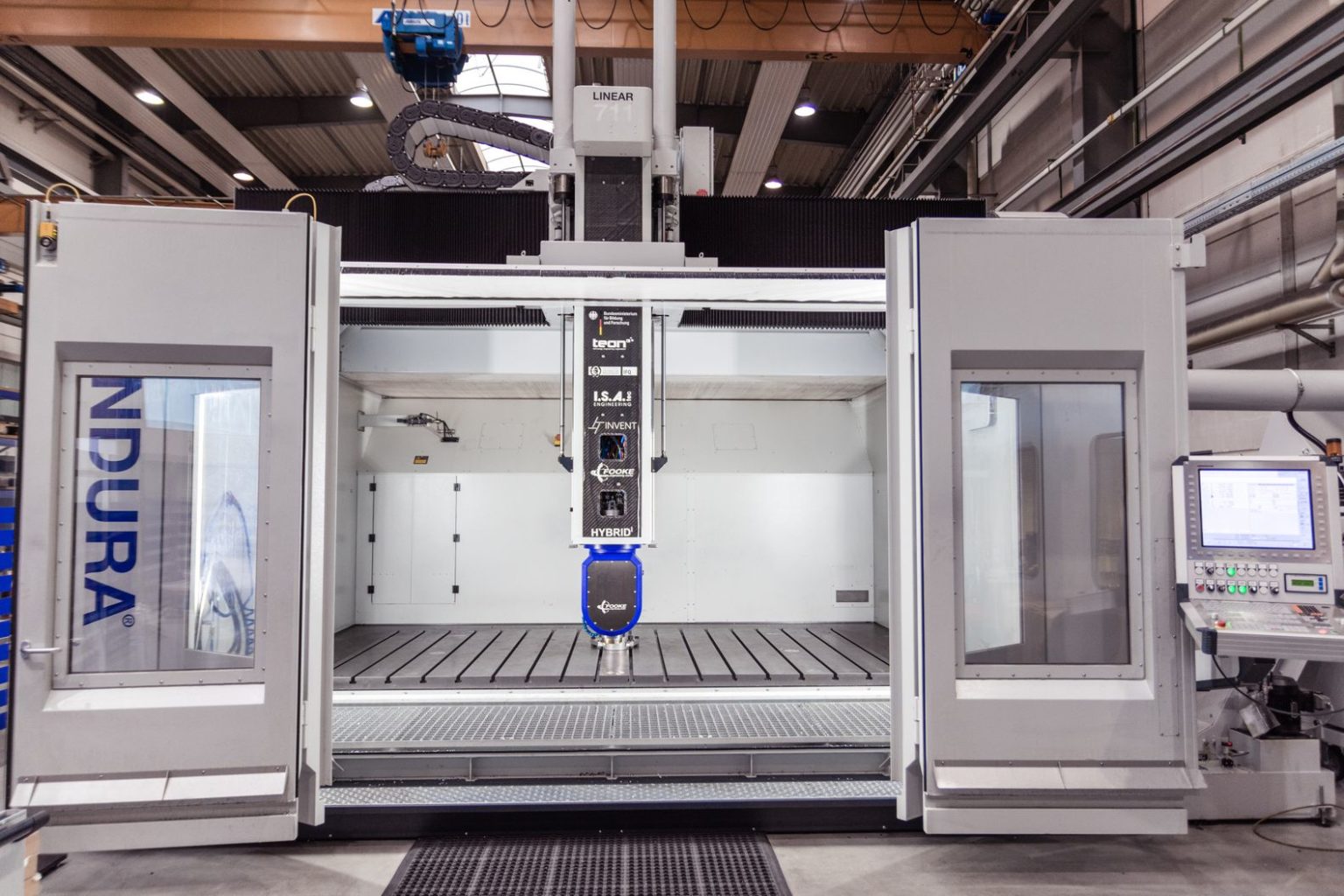

- HYBRIDi

to the HYBRIDi video - CFK-Span

- Effective

- KOSEL

- inteFix

Scientific instruments

Scientific instruments

The technology portfolio of INVENT offers exactly the heritage in terms of materials, design methods and manufacturing procedures that you expect for CFRP components in the scientific environment.

The team, from engineering to production, is familiar with the special requirements of these applications: from the highest precision to designs for applications in cryogenic environments or vacuum, outgassing-free materials to special property profiles with regard to electrical or thermal conductivity or dimensionally stable behaviour over a wide temperature range.

References:

- DESY

- CERN

- Large Binocular Telescope

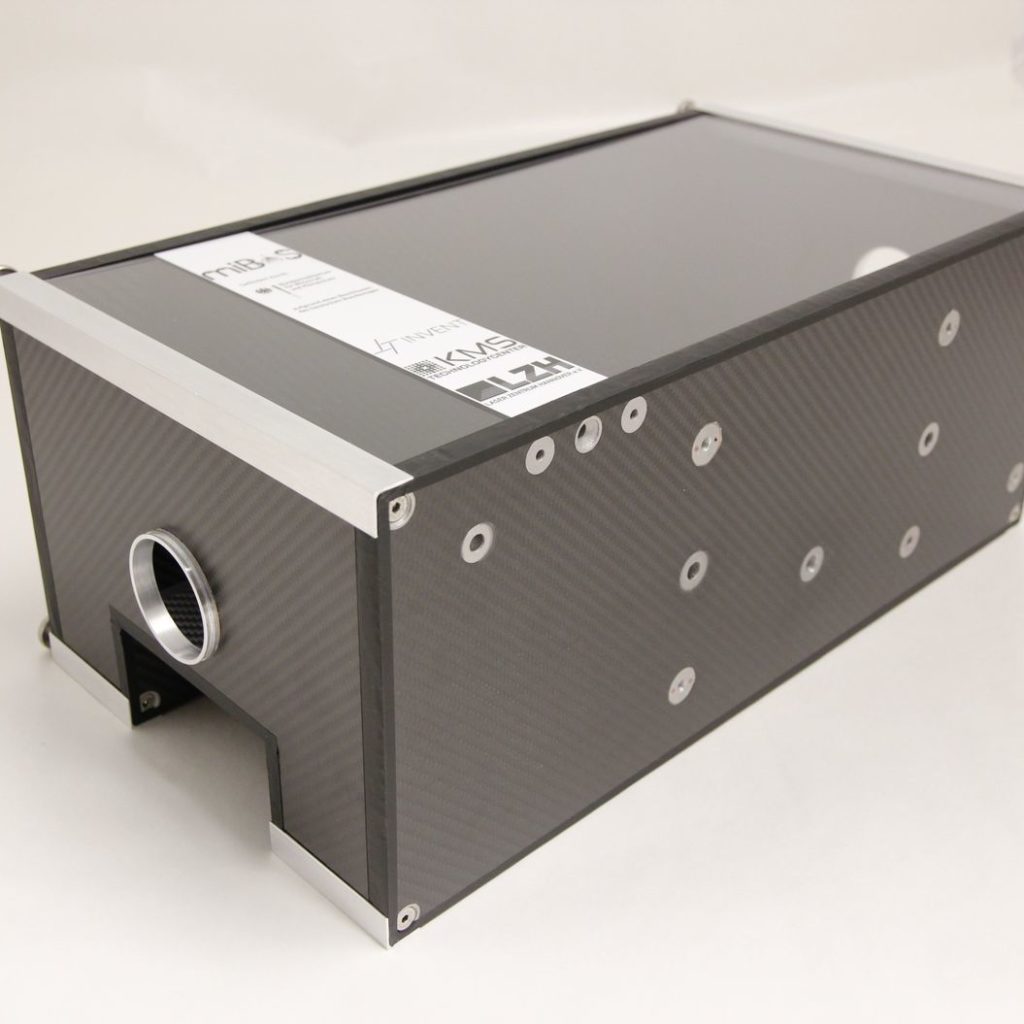

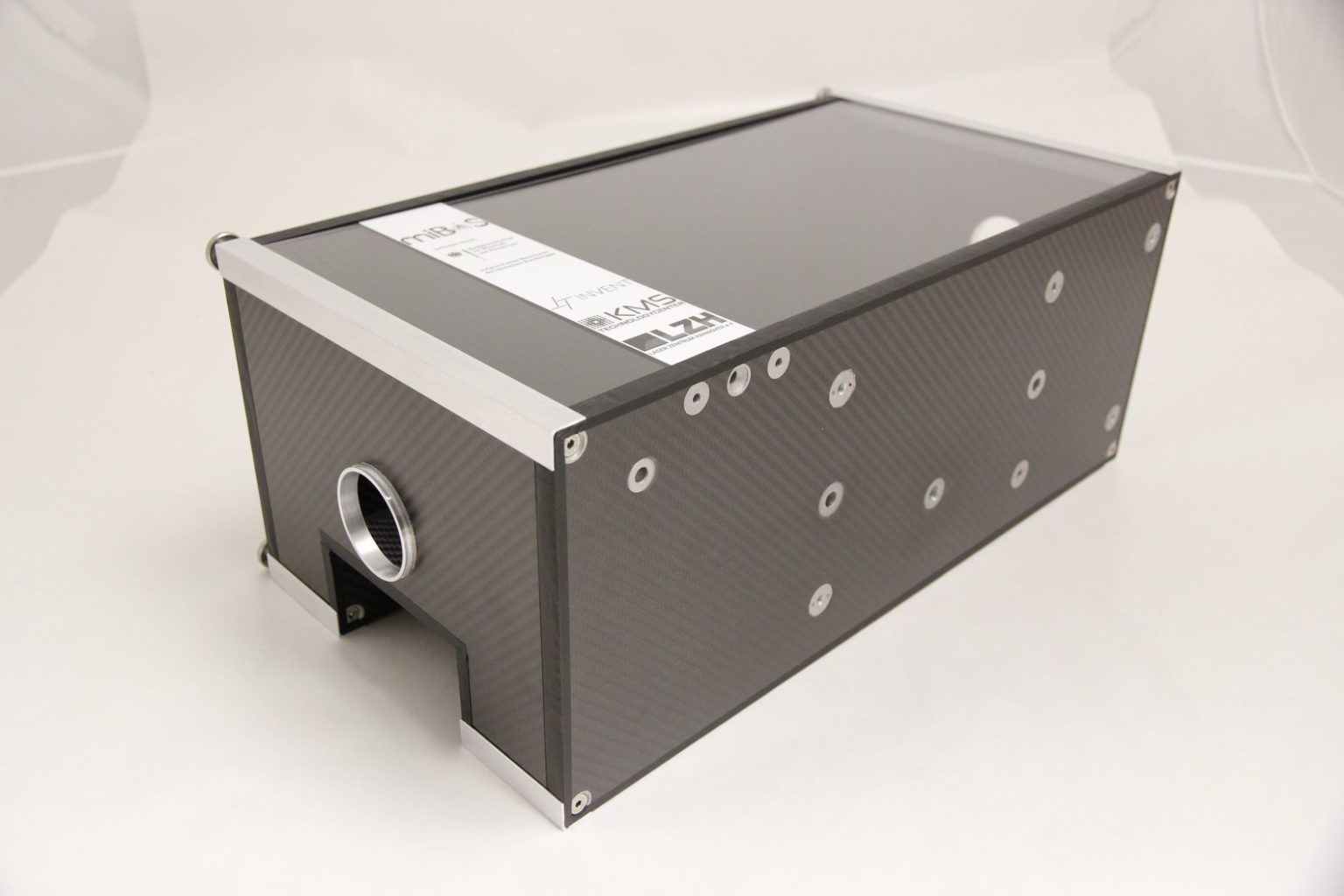

- miBoS

Sustainable Lightweight Design

Sustainable Lightweight Design

Fibre composite technologies show their strengths in the use phase, in which the high energy and material costs are compensated in many scenarios. INVENT develops strategies to make the use of fibre composites more sustainable, starting with design, through manufacturing processes and technologies to life cycle analysis and recycling.

In addition to the use of biomaterials, we develop processes that are less energy-intensive and have solutions in our portfolio that address the entire life cycle.

Innovative manufacturing processes allow us to reduce energy requirements in production. In product development, we examine which component scenarios are suitable for recycled materials. Innovative joining processes allow adhesive bonds to be released and components to be reused without impairing their mechanical properties.

References:

-

FiberEUse

-

SUSTAINair

-

RECREATE

-

ecoTECH

-

iFeZ

Biomaterials

Biomaterials

Biomaterials offer the potential to develop sustainable fibre composite components from the perspective of the raw materials. At the same time, additional technical value can often be exploited, such as the damping and crash behaviour of natural fibres or the intrinsic fire retardancy of certain resin systems. Renewable raw materials are also playing an increasingly important role in sandwich cores and fire protection systems.

These materials have accompanied INVENT GmbH since the company was founded, so that we can implement your application with the help of an extensive material database, calculation models and process know-how in such a way that the strengths of these materials are optimally utilised.

Where renewable raw materials reach their limits as a material system, sustainable fibre composite technologies are incorporated to offer a holistic solution.

- Schuberth Helme

- Ford Mustang GT (FourMotors)

- ecoTECH (CleanSky2)

- futureTEX 2020

- Natural fiber composite canadian

Smart structures and systems

Smart structures and systems

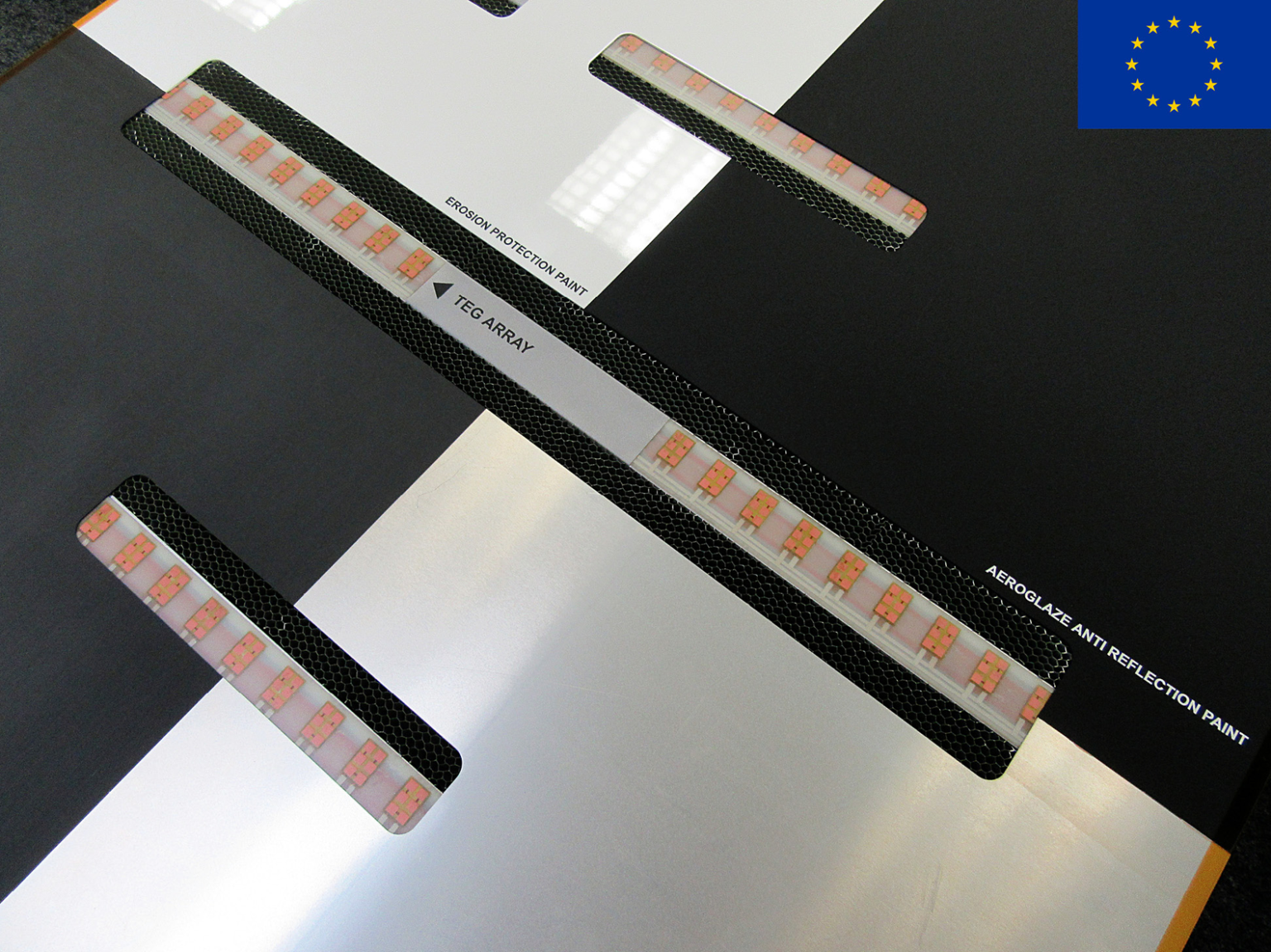

- Structural Health Monitoring

- Vibration sensors

- Accoustic emission

- Noise reduction

- Energy Harvesting

- SARISTU – and FAWASIS sensor network – structural monitoring

- Remote Detect Vibration Measurements

- KAMOS – combined acoustic and modal structure monitoring

References

saristu - Structure monitoring

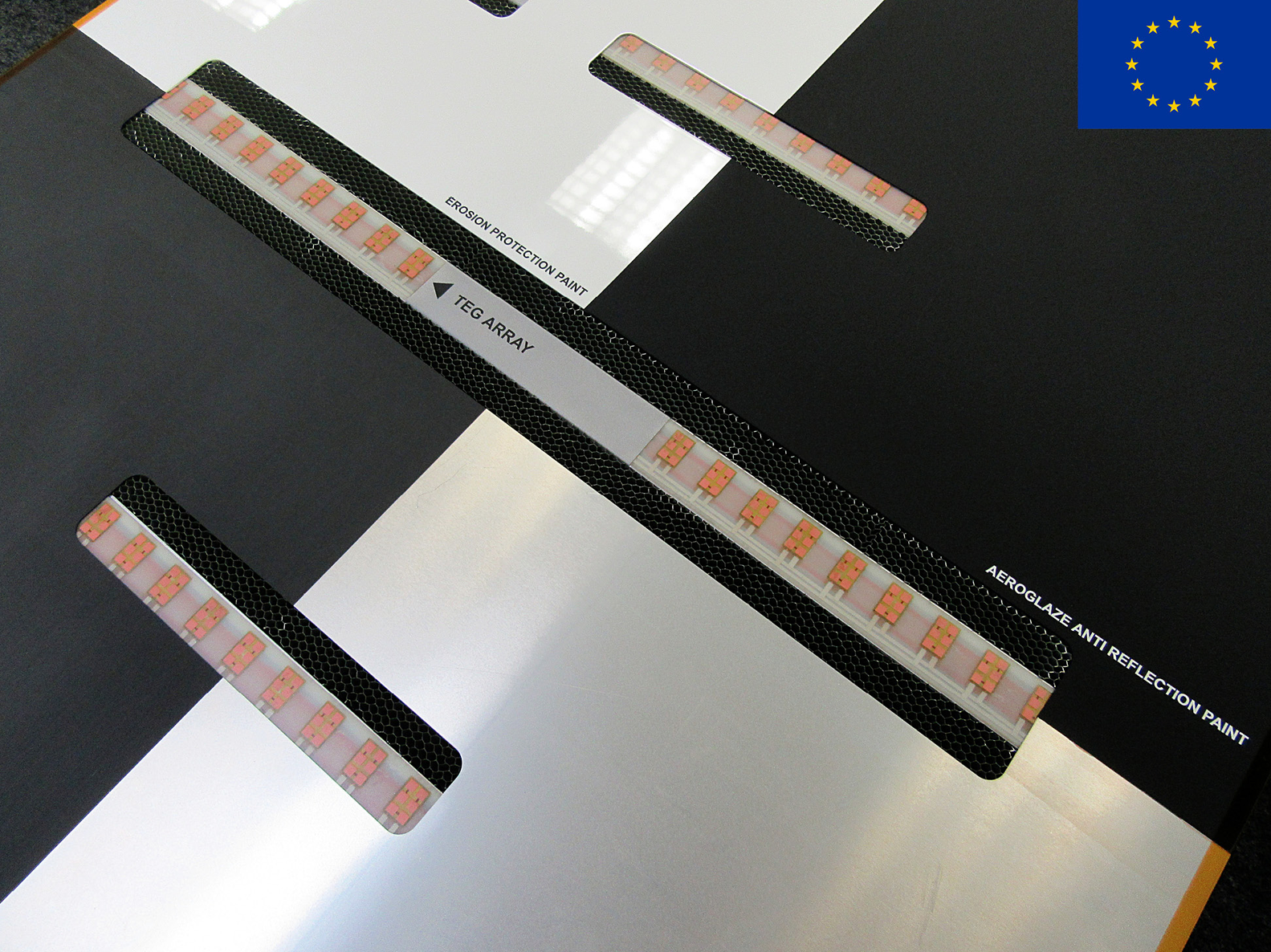

SARISTU – Structural Health Monitoring of a full-scale door enclosure structure of a civil aircraft

For more informations Cordis der Europäischen Union: …click here.

Remote Detect for Offshore Wind Turbines

Remote Detect for Offshore Wind Turbines

Automatic monitoring of underwater welds of offshore wind turbines using a submersible robot (ROV)

(RemoteDetect: BMWi – FKZ 03SX433A)

To see his video on the site of the Federal Ministry of Economy and Climate Protection: …click here

Automatic monitoring of underwater welds of offshore wind turbines using a ROV

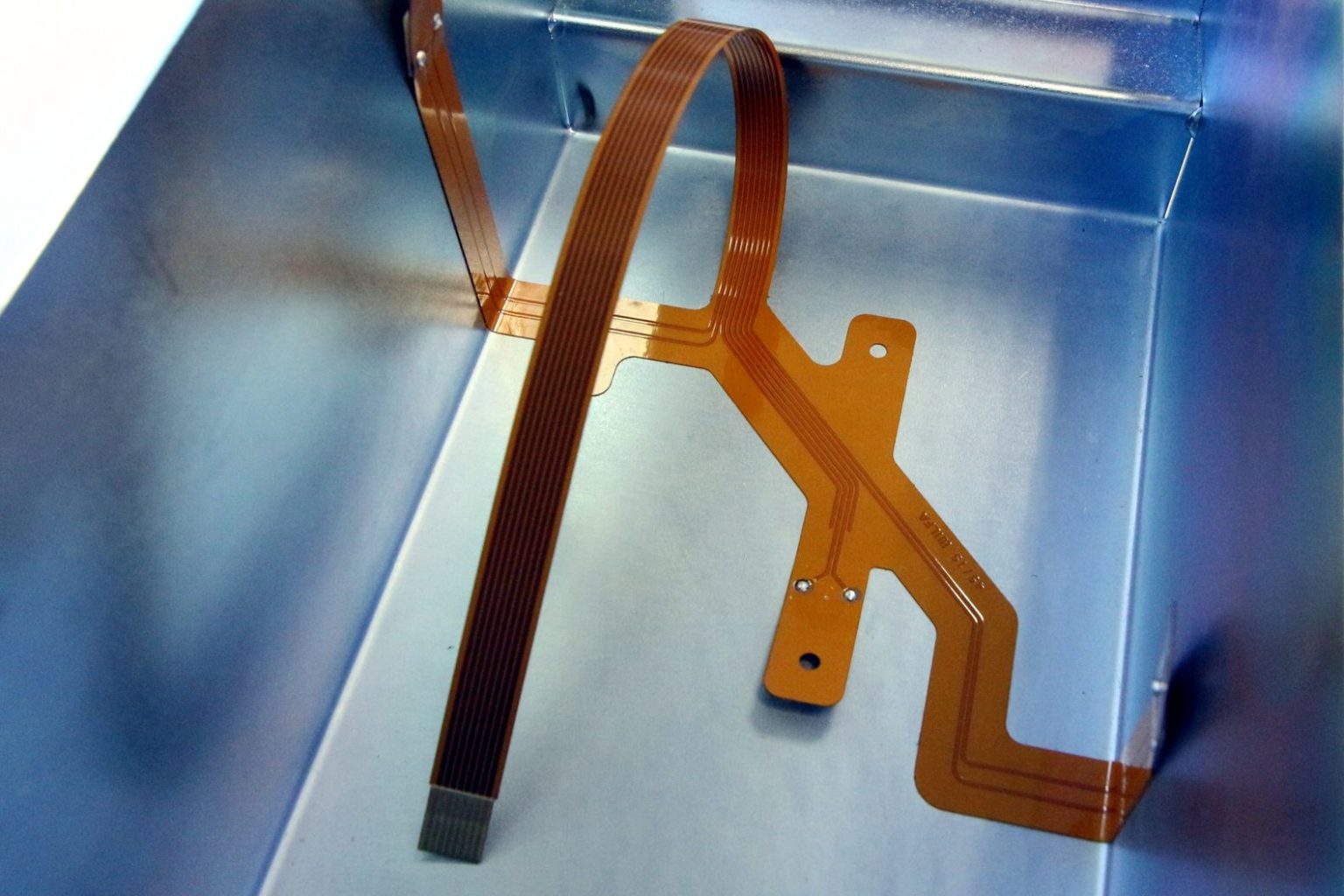

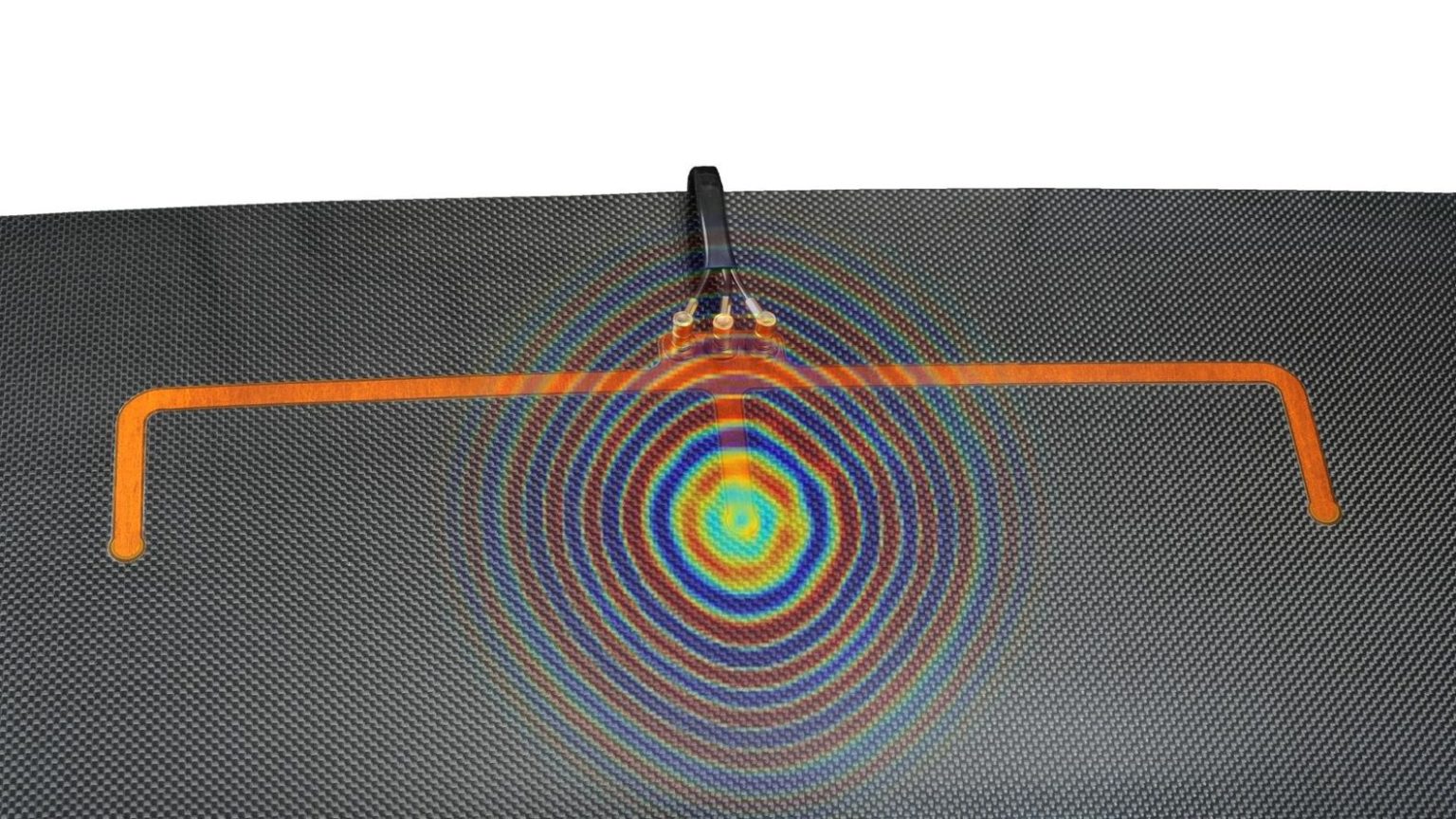

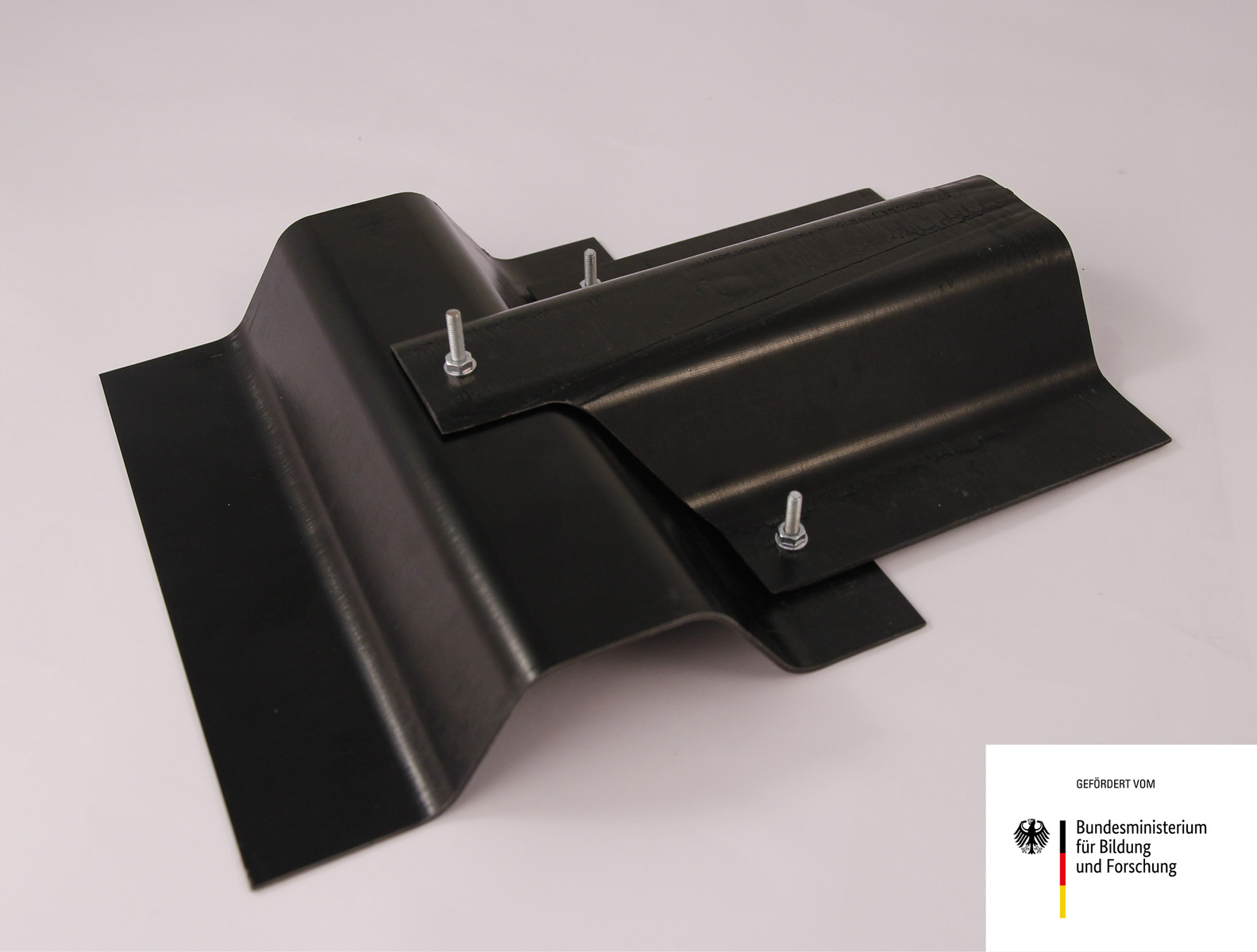

With the CoMoBelt® sensor collar, a measuring system was developed in the RemoteDetect project that is permanently installed on the foundation structure of offshore wind turbines and can monitor their integrity. This continuously reduces the need for costly on-site visits and thus lowers maintenance costs. Similar to a ring, the sensor collar is directly and permanently attached to highly stressed areas of the foundation structure, such as welds. This minimizes the impact of external biomaterial fouling on measurements and eliminates the need for strenuous and time-consuming manual cleaning of measurement sites by divers.

Special features: :

-

Shear wave transducer, SH0 waves, insensitivity to fouling on surface.

-

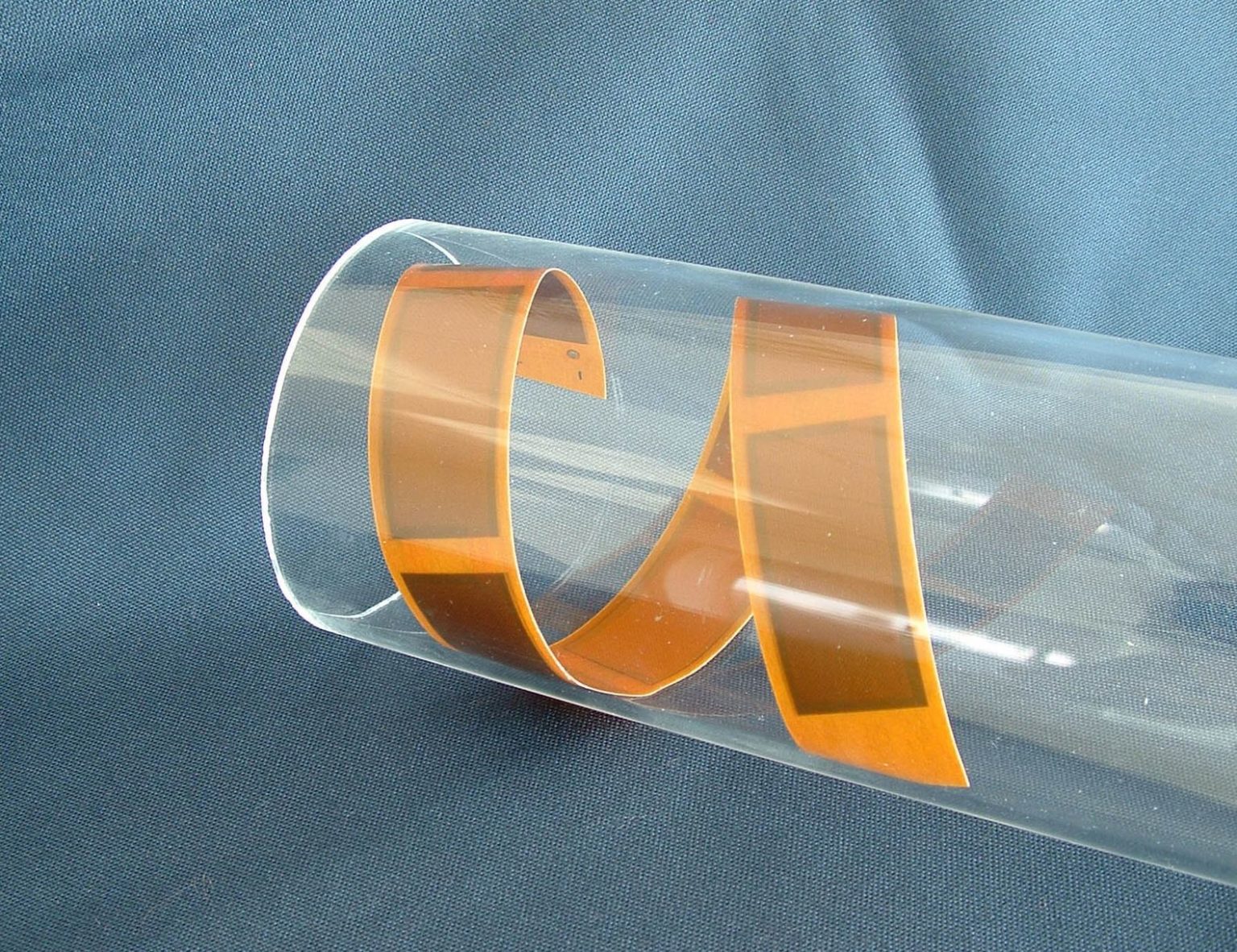

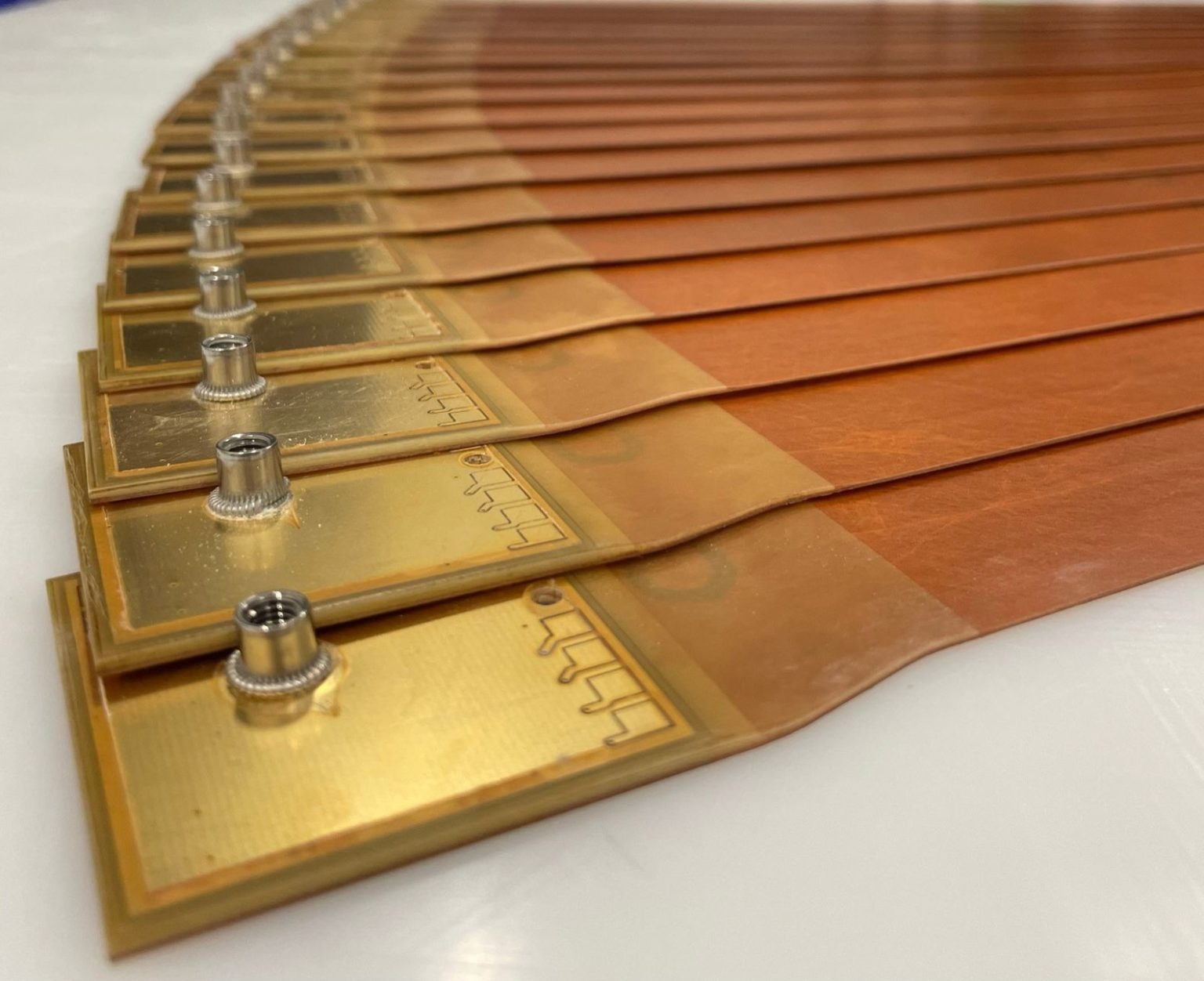

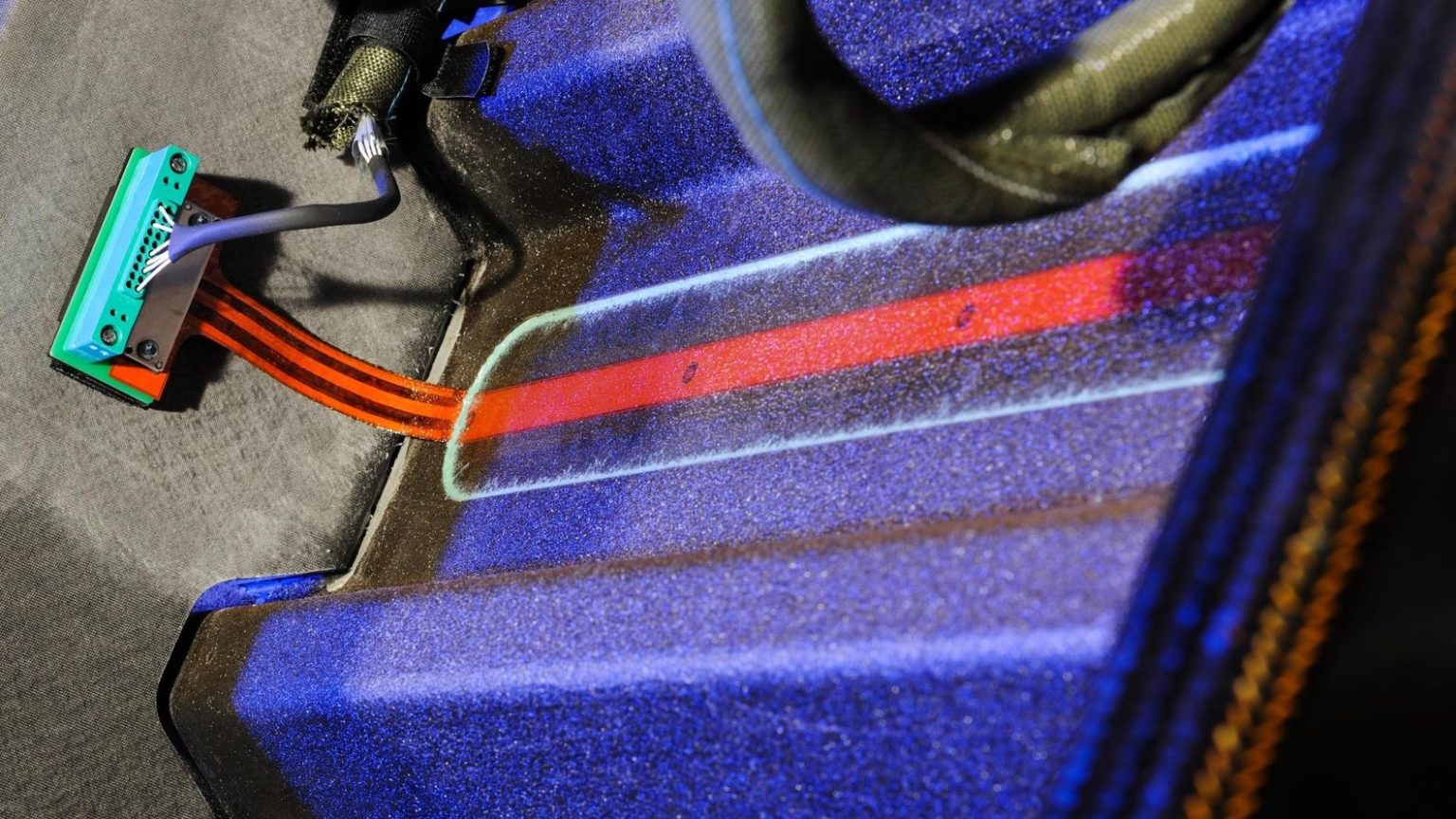

Flat conductor integration

FaWaSiS - Sensor Network

FaWaSiS

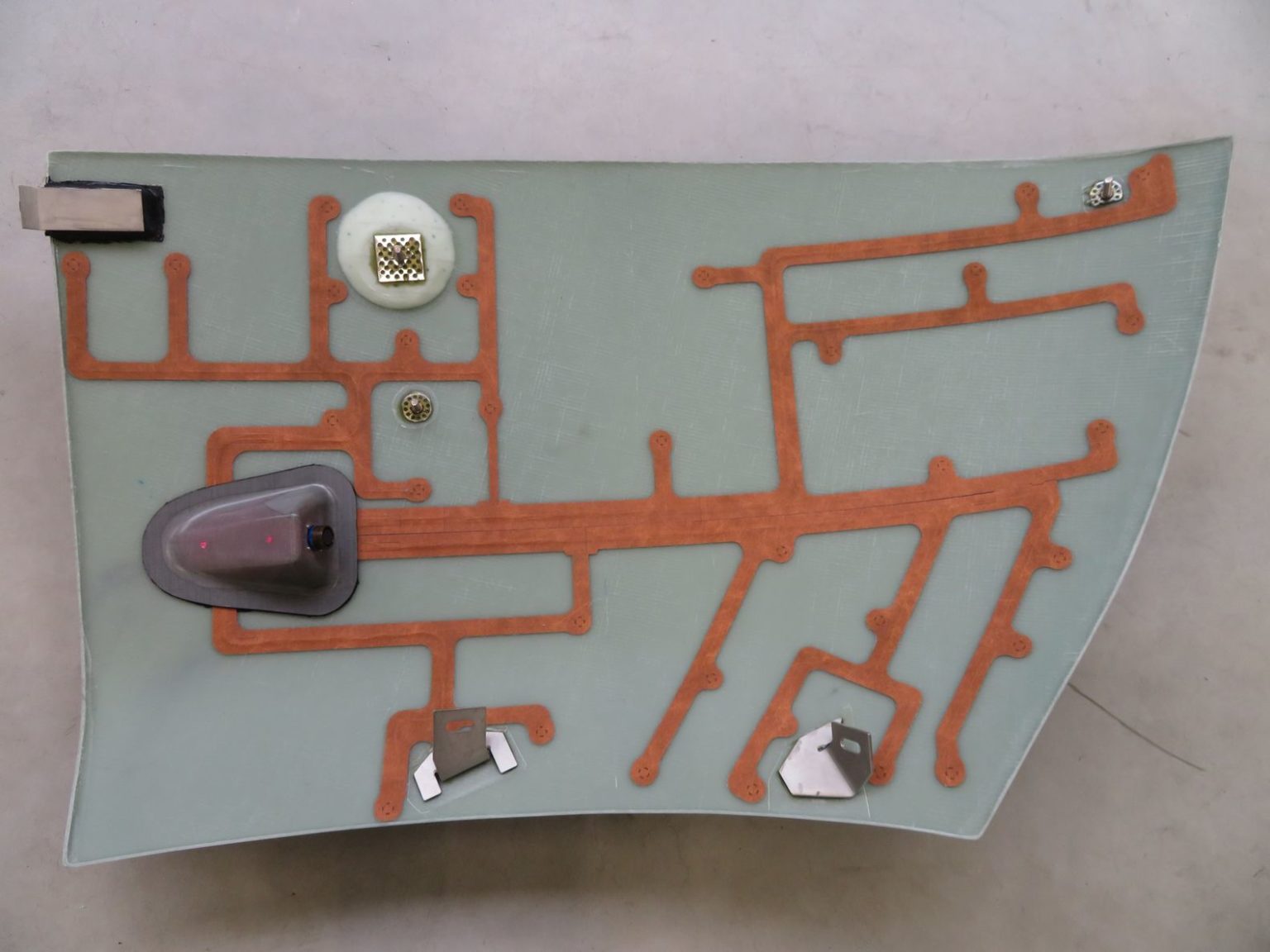

Sensor network for active Structural Health Monitoring of the side skirt of a 612 series multiple unit train.

Click here to go to his article with more information …read more

Special features: :

-

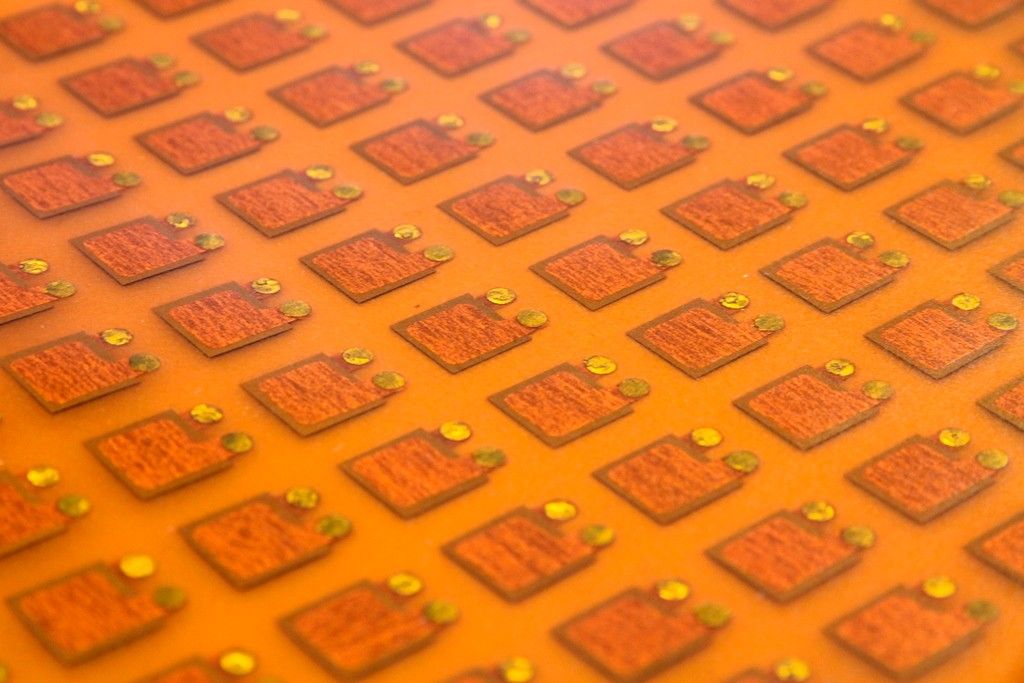

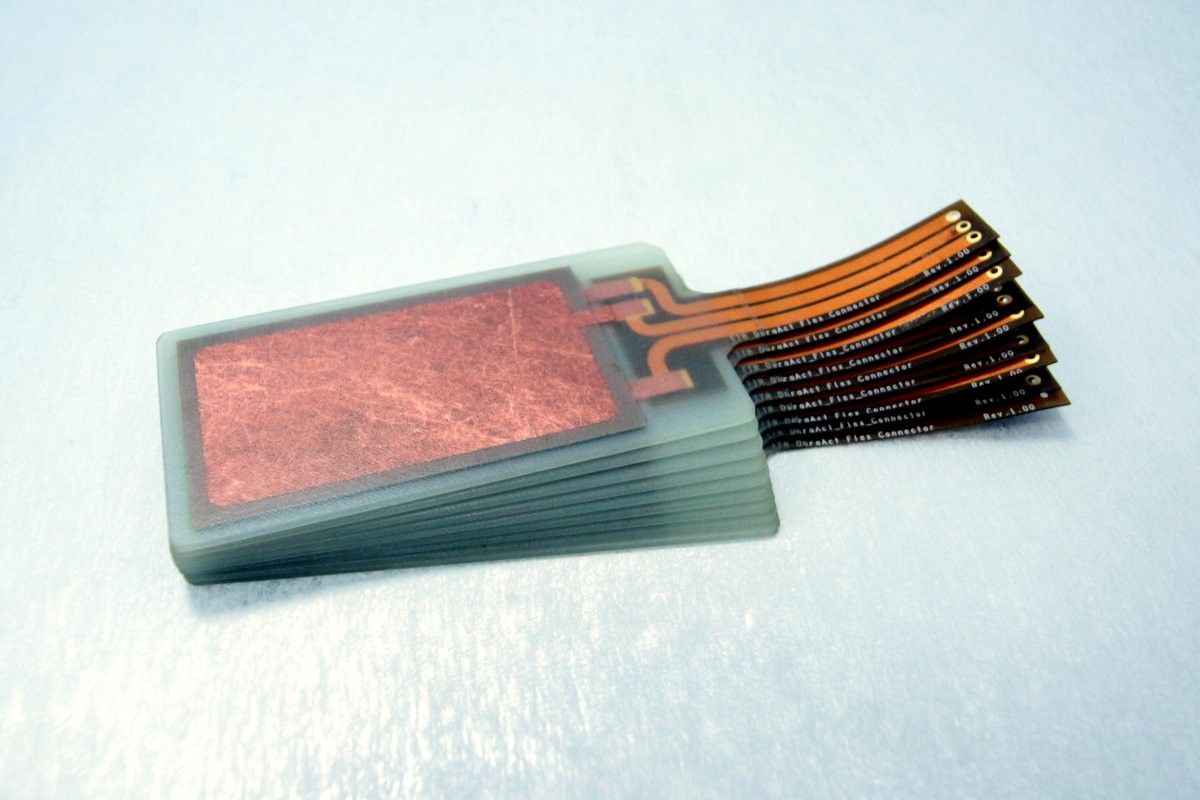

Large Sensor Network: All functional parts integrated in polymer encapsulation (Multiple ceramics, cables, …)

-

Military plug as the central connection of the piezos

SARISTU - Strukturüberwachung einer maßstabsgetreuen Tür- Umgebungsstruktur

Hier gelangen zur Seite von Cordis der Europäischen Union: …weitere Informationen.

Remote Detect bei Offshore Windanlagen

Automatische Überwachung der Unterwasserschweißnähte von Offshore-Windkraftanlagen mithilfe eines Tauchroboters ROV

(RemoteDetect: BMWi – FKZ 03SX433A)

Hier gelangen zu seinem Video der Seite vom Bundesministerium für Wirtschaft und Klimaschutz: …zum Video

Automatische Überwachung von Unterwasserschweißnähten mit einem ROV

Mit der Sensormanschette CoMoBelt® wurde im RemoteDetect Projekt ein Messsystem entwickelt, das dauerhaft an der Gründungsstruktur von Offshore-Windkraftanlagen installiert wird und deren Integrität überwachen kann. Das reduziert kontinuierlich den Bedarf an kostenintensiven Vor-Ort-Einsätzen und senkt damit die Wartungskosten. Ähnlich wie ein Ring wird der Sensorkragen direkt und dauerhaft an stark belasteten Bereichen der Fundamentstruktur, wie z. B. Schweißnähten, angebracht. Dadurch wird der Einfluss von externem Biomaterialbewuchs auf die Messungen minimiert und die anstrengende und zeitaufwändige manuelle Reinigung der Messstellen durch Taucher entfällt.

Besonderheiten:

Scherwellenwandler, SH0-Wellen, Unempfindlichkeit ggü. Bewuchs auf Oberfläche

Flachleiterintegration

FaWaSiS

Sensornetzwerk zur aktiven Strukturüberwachung der Seitenschürze eines Triebzugs der Baureihe 612.

Hier gelangen zu seinem Beitrag mit weiteren Informationen: …zum Beitrag

Besonderheiten:

Großes Sensornetzwerk: Alle Funktionsteile in Polymerkapselung integriert (Mehrere Keramiken, Kabel, …)

Militärstecker als zentraler Anschluss der Piezos

Research and Development Projects

Research and Development Projects

Technological expertise in lightweight design is the foundation of INVENT’s quality. That is why we have been focusing intensely on research and development since our founding in 1996, in order to stay fit for the future in all business areas through the further development of new technologies. In doing so, we work closely with research institutes, universities and the development departments of renowned companies, thus driving industrial lightweight construction into ever new areas of application.

The focus is on both current and promising topics in the field of functional materials, process development, innovative sensors and actuators, functional integration and, of course, novel components that have never been realised before. New technologies are made commercially viable and open up the best perspectives for the potential of lightweight design in all business fields of INVENT.

From aerospace to automotive and rail applications as well as machine components – we demonstrate our expertise in the initiation, planning and implementation of federal, national and EU-wide collaborative projects with our own competence team.

National funded projects

- BMWK

- BMBF

EU R&D programmes:

- FP7

- H2020

- JU Clean Sky 2

Aviation

Space

CONTACT

Tjark Sonnemann

Tel. +49 531 24466-285

tjark.sonnemann@invent-gmbh.de